What are ways to reduce metal manufacturing costs?

- Consolidate services

- Choose a well-located, well-equipped fabrication shop

- Identify the right materials and quantities

- Simplify your design

- Look for supplier transparency

- Consult your manufacturer

Successful business owners are constantly thinking of new and creative ways to stay cost-efficient and maximize their earnings. And when it comes to manufacturing and fabricating metal products, such budgeting is important. Industry veterans know it’s crucial to find small tweaks in production to create big savings.

To that end, here are six simple ways to reduce metal manufacturing costs and avoid additional expenses that can add up quickly.

Consolidate Services

When creating your metal products, you may be employing multiple service providers — engineering design, material sourcing, logistics, and many other processes that can be performed by different companies. This creates a complexly wide supply chain, which may not be productive and cost-efficient.

It’s worth looking at these processes as a whole and determining what savings are possible if you consolidated them under one company. Streamlining your supply chain is a great way to simplify the manufacturing process and keep costs down, as there’s only one company to communicate with instead of four or more.

Choose a Well-Located, Well-Equipped Fabrication Shop

Location matters — whether you choose a fabrication shop in the same city or have your products made in another country, transportation costs are inevitable for your project. Part of ensuring that your product is made in the most cost-efficient manner possible means weighing the value you receive from your manufacturing partner versus transportation and logistical costs.

You may be able to find a well-equipped partner that is closer in proximity to your business. This is a crucial point as your partner should be easily accessible, making communication, logistics, and quality control much easier when compared to a partner in a different time zone altogether.

Further, your chosen partner should be well-equipped in both technology and know-how to provide consultations and unique programs designed to cut costs. When evaluating possible partners, look out for companies that:

- Recommend ways to improve the manufacturability and cost-effectiveness of your product.

- Provide insights on how to streamline metal manufacturing services

- Offer multiple manufacturing and value-adding services, giving you flexibility with your product.

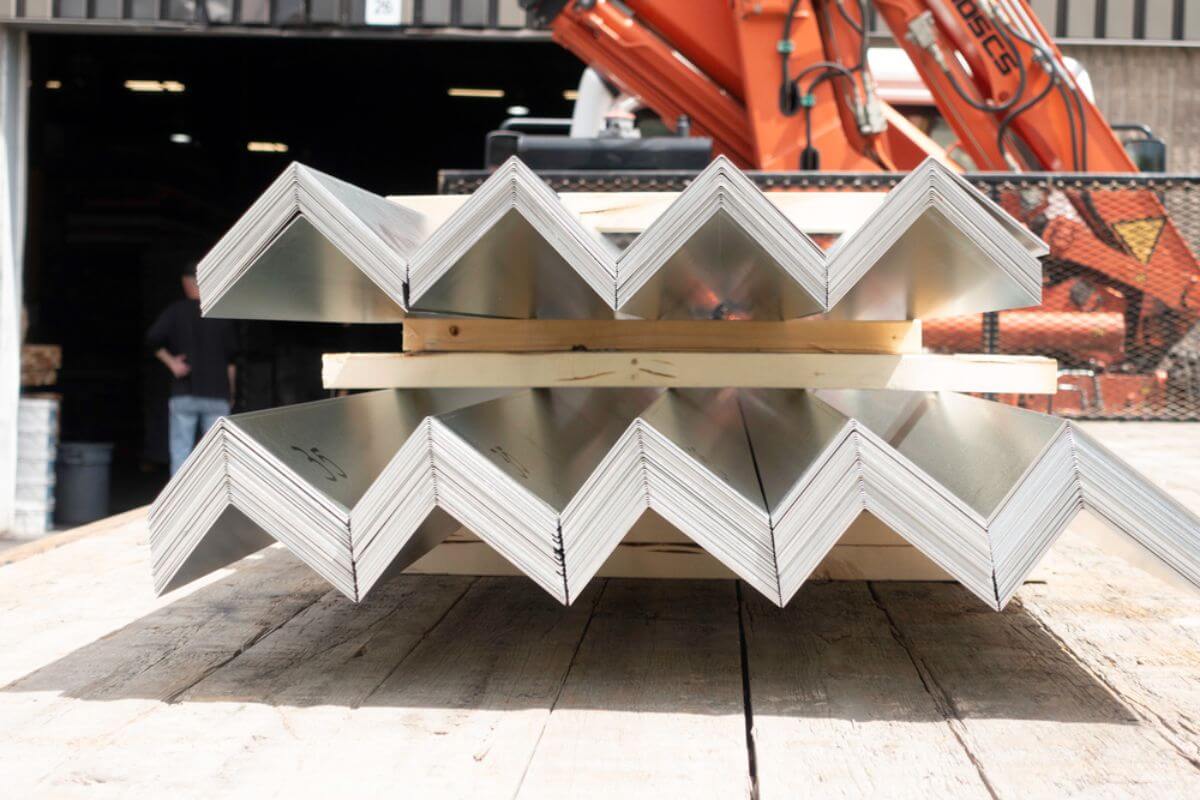

Identify the Right Materials and Quantities

The materials you use will be another major driver in your overall costs. Some metal materials will be more expensive than others, while others may be difficult to source or fabricate.

Before settling on a material, ask yourself if you can switch to cheaper metals and if this switch will cause any problems with product design, quality, or production. If using another material doesn’t drastically impact your product’s usability, you should consider it.

When evaluating possible economic alternatives, keep the following factors in mind:

- Whether a thinner format of the metal is better than a thicker format. Thicker metals have increased milling and cutting costs.

- If standard production metals that are easily fabricated are better than rarer metals that you were initially considering.

- If your fabrication partner offers mill-direct buying options. Doing so allows them to negotiate better prices on your behalf. Note that this option will not always be available, but fabricators with a robust supply chain can offer other ways to reduce your costs.

- Standard sizing and gauging will always cost less than custom measurements. Consider if your part truly needs custom sizing, or if it can be made with what is standard-sized or commonly used.

Simplify Your Design

Just as a product must be developed to deliver end-user efficiency, it must also be designed for production efficiency. In this case, your fabrication partner may be able to offer assistance in simplifying and adjusting your design to be fit for productionto be fit for production.

An experienced metal fabricator will help you achieve:

- Tight tolerances — Products with exact specifications will have tolerances that can’t be exceeded. Metal fabrication requires tight measurements, and it will be critical that designs account for those accordingly. On the other hand, if tolerances are unnecessarily tight, fabrication becomes more difficult and expensive than absolutely necessary — so a balance must be struck.

- Flexibility — Experts will point out where to switch materials for more common gauges of metal, if possible. They may also design parts that can be used in more than one way.

- Simplification — The skilled designers your fabricator employs will know how to keep your design simple and lines clean. When producing a final design for fabrication, simpler parts are always easier and cost less to produce.

- Automation — Fabricators will be able to automate parts of the fabrication process, and create designs that are compatible with CNC machinery.

Look for Supplier Transparency

You must understand where your money is going to assess your production budget fully — there’s no way around it. Many companies struggle to capture the costs in several fabrication areas, such as:

- Quality control

- Labor variation

- Maintenance

- Supplies

- Consumables

- Freight charges

- Overhead

Ask your fabrication partner for budget transparency. This enables you to see what exactly you’re spending in every manufacturing phase, and which steps are generating the most cost. Some partners will ensure fixed pricing, meaning you won’t have to shoulder cost variations related to labor, quality, or other unpredictable issues.

You should always work with a partner who is honest with project expenses and takes the time to explain each of these areas. The better you understand their processes and the benefits they provide, the more you’re able to save.

Consult Your Manufacturer

Lastly, consult your manufacturer. They will likely have years of experience and expertise on how to reduce the cost of metal fabrication projects. While you may be more knowledgeable in different aspects of your business, production efficiency is their specialty.

They can assess manufacturing processes for possible areas of improvement, as well as provide solutions. They may also know of current trends and market developments you can take advantage of to cut costs. Once you and your metal manufacturer develop a cost-efficient strategy, you stand to have more flexibility with your budget.

Key Takeaway

Keeping within budget can be challenging for many companies — especially when you’re interested in creating metal products. But, with these six ways to reduce metal manufacturing costs, you can streamline production without sacrificing the quality of your products.

That being said, these strategies rely on working with an experienced and dedicated local metal fabricator — like Regan Industrial Sales, Inc.. We are a professional one-stop metal fabricator for all your metalworking needs. Message Regan Industrial Sales, Inc. today to learn more about how we can assist you with your metal project.