How does the quality of construction materials impact building safety?

- Provide structural integrity

- Ensures proper load-bearing

- Enhances fire resistance

- Secures durability and longevity

- Helps in disaster resilience

- Facilitates regulatory compliance

Overview

- High-quality construction materials are essential for safe, durable, and resilient buildings.

- In the Philippines, factors like humidity, coastal air, and natural hazards make certified steel critical for structural integrity, load-bearing, fire resistance, disaster resilience, and regulatory compliance. Inferior materials increase collapse risk, costs, and legal liability.

When it comes to mixed-use developments, industrial facilities, or critical infrastructure, the construction materials you choose are more than just building blocks—they form the foundation of safety and long-term performance.

In the Philippines, for instance, local conditions such as high humidity, heavy rains, and salty coastal air can challenge even the strongest materials. Coupled with aging infrastructure and inconsistent material standards, these factors make careful evaluation of suppliers and products essential.

In this article, we’ll take a closer look at how the quality of construction materials impacts building safety, while providing practical guidance to help you make informed decisions that protect both your projects and your investment.

Provide Structural Integrity

Material quality impacts safety by keeping a building’s framework aligned and stable under stress. High-grade steel beams and columns resist bending, twisting, and warping, preventing weak points that can compromise the structure during wind, vibration, or heavy loads. Lower-quality materials, on the other hand, can gradually deform, creating misalignments that propagate through the building.

For instance, in multi-story facilities, steel beams that maintain their shape keep floors level and connections tight. This ensures that stress is distributed evenly across the framework, showing clearly how reliable materials directly support structural integrity and prevent failures over the building’s life.

Ensures Proper Load-Bearing

The quality of materials determines how safely a structure can carry intended loads. High-grade steel with verified specifications distributes weight evenly across floors and supports, preventing joints and connections from being overstressed. Materials that fail to meet these standards risk bending or cracking, which can compromise both occupant safety and operational functionality.

In industrial projects with heavy machinery or storage systems, selecting materials with proven load-bearing performance ensures floors and platforms stay rigid under weight. This prevents deformation or sudden failure, demonstrating how material quality directly maintains safety by keeping structures capable of carrying their designed load

Enhances Fire Resistance

High-quality construction materials contribute to safety by maintaining structural stability during fire events. Steel sections with verified fire performance retain strength longer at elevated temperatures, keeping key load paths intact and reducing the risk of collapse. Using materials without proven fire resistance can lead to premature weakening and structural failure.

For example, in commercial or industrial buildings, fire-rated steel beams preserve floors and connections long enough for evacuation and fire control. This illustrates how choosing materials with known fire performance directly protects both occupants and the building itself, linking material quality to overall safety.

Secures Durability and Longevity

Durable, high-quality materials affect safety by resisting wear, corrosion, and fatigue over time. Steel components with consistent composition and protective coatings maintain their strength and shape under environmental stress, preventing gradual degradation that could create structural hazards.

In coastal or humid areas, treated steel members hold up against moisture and corrosion, keeping connections stable and walls aligned. By selecting materials designed to last, you ensure that the structure remains safe and functional for decades, reducing risks from long-term deterioration.

Helps in Disaster Resilience

Material quality directly impacts how well buildings withstand natural hazards. Steel frames and bracing with consistent structural properties absorb and redistribute forces from typhoons, earthquakes, and heavy rains, preventing collapse or sudden failures. Low-quality or inconsistent materials can fracture or deform, compromising safety under extreme conditions, a common issue during monsoon-season in the Philippines.

For example, a well-engineered steel frame in a typhoon-prone area can preserve key connections and prevent roof or wall failures. This demonstrates how verified, high-quality materials improve disaster resilience, keeping occupants and critical infrastructure safe.

Facilitates Regulatory Compliance

Using high-quality, certified materials affects safety by ensuring that structural components meet building codes and standards. Steel sections with mill test certificates and supplier verification provide documented proof of strength, ductility, and dimensional accuracy, which supports compliance with PNS, ASTM, or ISO standards.

For instance, integrating certified steel in a high-rise project confirms that beams and columns meet design specifications. This not only avoids legal or financial penalties but also ensures that the building performs safely under expected loads, showing clearly how material quality directly supports regulatory and structural safety.

Risks of Inferior Materials

Understanding how the quality of construction materials impacts building safety also becomes clear when you consider the consequences of using inferior materials.

Sudden Collapses

Weak or inconsistent materials can fail unexpectedly, leading to sudden collapses. Floors, walls, or supports made from substandard steel or concrete may bend, crack, or break under pressure, putting workers, residents, and equipment in immediate danger.

Increased Costs

While low-quality materials may seem cost-effective initially, they often require frequent repairs or complete replacements over time. Poor material performance can also cause project delays, downtime, and the need for additional reinforcement, making long-term costs significantly higher.

Legal and Financial Repercussions

Using non-compliant or substandard materials can result in fines, lawsuits, or penalties from regulatory authorities. Beyond legal risks, compromised builds can damage your professional reputation and may lead to liability claims if structural failures cause injury or property damage.

Find Quality and Reliable Construction Materials at Regan Steel

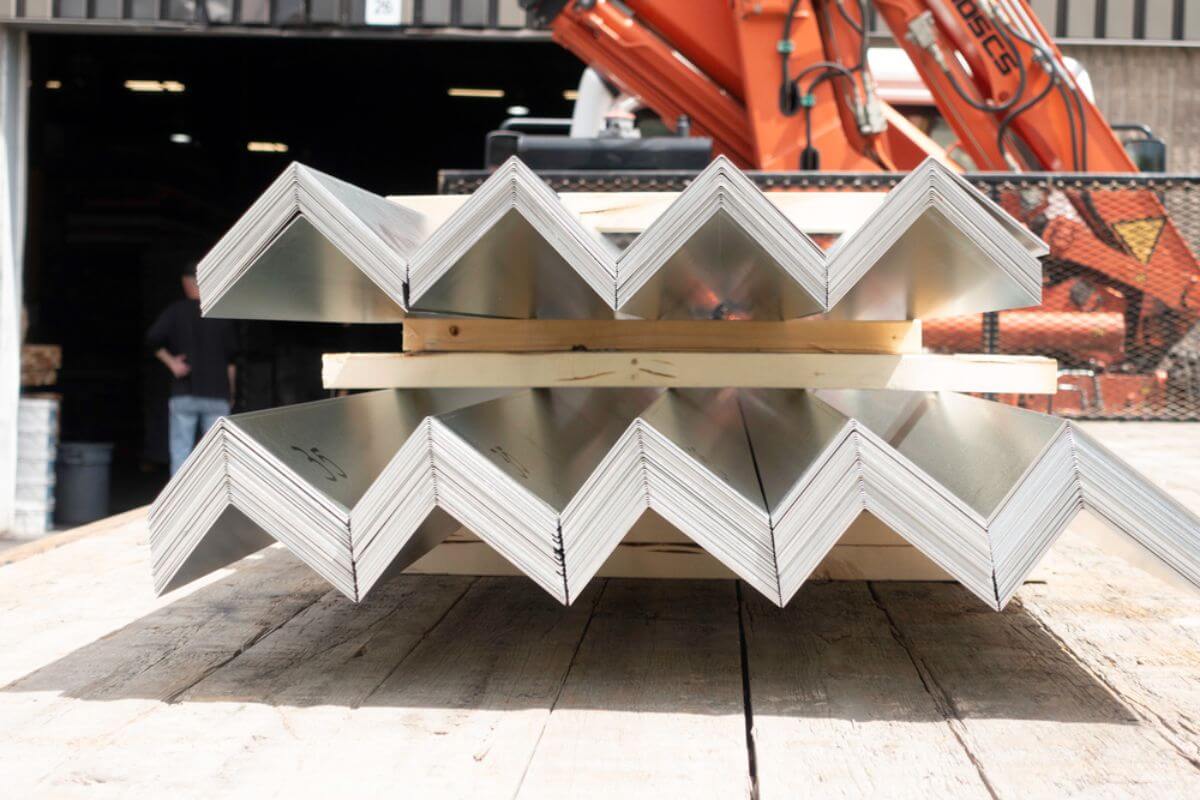

At Regan Steel, we provide a wide range of steel products that meet the highest standards of quality and safety, giving you confidence in every project. Our certified materials are designed to perform reliably under environmental and structural demands, helping ensure your buildings remain safe and durable.

Beyond supplying high-quality steel, we focus on innovation and responsive customer service. With our expertise and support, you can streamline sourcing, reduce risks, and work with a partner committed to delivering both reliability and long-term value for your construction projects.

Key Takeaway

Ensuring your build’s safety starts not just in its foundations but also in your materials, guiding every decision toward stronger, more resilient, and longer-lasting structures.

Partner with Regan Steel, your trusted source for high-quality construction materials. Our certified products are designed to ensure durability, safety, and reliability for every project. Contact us today to learn how we can help you build stronger, safer structures.