What is the difference between I Beams and H Beams?

- Applications

- Shape and design

- Dimension and weight

- Load bearing capacity

- Span length

Overview

- Learn the key differences between I beams and H beams, including their applications, design, load-bearing capacity, and span lengths.

- Whether for residential or heavy-duty commercial projects, understanding these distinctions will help you choose the right beam for your construction needs.

Understanding the difference between I beams and H beams is a must not just for contractors but for homeowners as well. Knowing the distinction helps ensure your project meets safety standards, allows construction to proceed smoothly and efficiently, and can even save time and money.

In this article, we’ll take a closer look at the key differences between these beams and how they impact your construction choices. Whether you’re working on a large-scale project or a home renovation, understanding these differences can guide you in selecting the right beam for your specific needs.

Applications

Knowing the difference between I beams and H beams starts by knowing their different applications. Both serve unique roles in construction due to their structural differences.

I beams are commonly used in applications that require moderate load support, such as residential buildings, bridges, and smaller structures. They are particularly effective for direct loads but may be less resistant to twisting forces due to their narrower flanges.

In contrast, H beams are ideal for heavy-duty applications, offering superior load-bearing capacity. They are typically used in large commercial buildings, bridges, and industrial structures where substantial load resistance is necessary.

Shape and Design

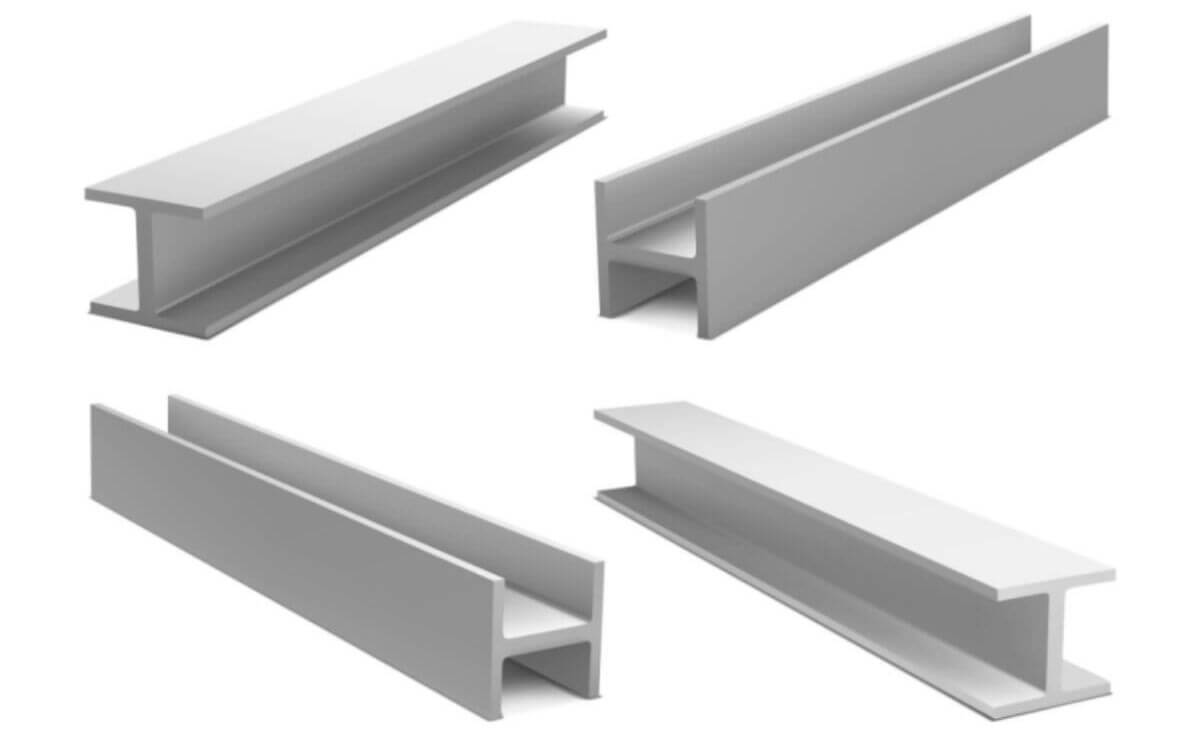

Another key difference between these beams lies in their shape and design. I-beams feature a cross-section resembling the letter “I,” consisting of two horizontal flanges connected by a vertical web. This design typically tapers from a thicker inner edge to a thinner outer edge, usually at a ratio of 1:6 or 1:10. This tapering helps with load distribution but limits torsional resistance.

In contrast, H-beams have a cross-section shaped like the letter “H,” with parallel flanges that are equal in width and thickness. The web connecting these flanges is thicker than that of I-beams, providing enhanced stability and strength. The absence of flange inclination allows for better load distribution across the entire beam.

Dimension and Weight

The dimensions and weight of I-beams and H-beams are important factors that affect their use and performance in construction. H-beams typically have wider flanges than I-beams. They also tend to have a deeper web, adding to their strength and ability to support larger weights.

I-beams, on the other hand, have narrower flanges that taper towards the web, making them less sturdy than H-beams. Their shallower web limits their ability to bear weight compared to H-beams.

Weight-wise, H-beams are generally heavier than I-beams because of their larger size and thicker web. This extra weight gives them better load-bearing and stability, while I-beams are lighter and easier to handle, which can be useful in situations where weight is a concern.

Load Bearing Capacity

As essential components in construction, these beams are designed to bear specific loads. For instance, if you need something with a higher load capacity, H-beams are the better choice.

Their wider flanges and thicker web help distribute loads more evenly, making them ideal for heavy-duty applications like bridges, industrial buildings, and high-rise structures. The thicker design also makes them more resistant to bending and shear forces, allowing them to support heavier loads without much deformation.

On the other hand, I-beams are better suited for moderate loads. They’re designed mainly for vertical loads and have a lower load capacity compared to H-beams. Their narrower flanges and shallower web make them less effective at handling lateral loads and bending stresses.

Span Length

Span length refers to the distance between the centers of two supports that hold the beam in place. It plays a key role in determining how much load a beam can handle and how it will perform under different conditions.

H-beams can typically support spans of up to 330 feet (around 100 meters), depending on factors like load requirements, beam size, and material properties.

I-beams, on the other hand, are generally suitable for spans between 33 and 100 feet (roughly 10 to 30 meters). Their narrower flanges and shallower web limit their ability to carry heavy loads over longer distances.

Discover Quality Steel Products Here at Regan Steel!

As a leading steel supplier in the Philippines, Regan Steel offers a wide range of high-quality steel products suitable for various applications.

We prioritize quality and reliability, ensuring all our products meet international standards. With a strong commitment to customer satisfaction and years of industry experience, we’ve earned the trust of clients across multiple sectors, including construction, infrastructure, automotive, and more.

Key Takeaway

Understanding the key differences between these beams equips you with the knowledge to make informed decisions for any project, large or small. With this insight, you can confidently approach your next project and ensure the best possible results.

Discover quality beams and a wide range of steel products at Regan Steel, where we prioritize durability, reliability, and top-notch performance. Whether you’re working on a small-scale project or a major construction venture, we have the right solutions to meet your needs. Contact us today to learn more!