What are the challenges that the steel industry in the Philippines is facing today?

- Production and capacity

- Influx of substandard steel

- Supply chain and logistics

- Standards and workforce

Overview

This article highlights the importance of reliability, quality, and product range in selecting a steel industry partner.

It emphasizes on-time delivery, strict adherence to engineering standards, and comprehensive product availability as critical factors that help projects stay on schedule, reduce procurement risks, and ensure long-term structural safety and durability.

The steel industry in the Philippines plays a vital role in powering the country’s construction, infrastructure, and economic development, making it one of the most essential sectors in the nation.

But like any major industry, it also encounters hurdles that can affect productivity, quality, and long-term growth. These real-world issues shape how projects are carried out across the country, which is why understanding them is important for businesses and developers.

In this article, we will explore the challenges facing the steel industry in the Philippines and how they impact the sectors that rely on it.

Production and Capacity

With the Philippines consuming around 10 million tonnes of steel every year, 55% rebar and 45% flat steel, local mills simply can’t keep up, forcing you to rely heavily on imports. This becomes a challenge because imported steel is affected by global pricing, shipping delays, and unpredictable availability.

As a contractor or project developer, this creates planning risks: budgets fluctuate, lead times extend, and project schedules become harder to control. When supply isn’t steady, you may struggle to secure the exact grades or quantities you need, making it harder to maintain consistent progress across multiple sites.

Influx of Substandard Steel

The growing presence of substandard steel puts your projects and the people who use them at serious risk. Just last year, a steel industry group found poor-quality rebars in the Mindanao market enough to build more than 10,000 houses per month, potentially endangering up to 30,000 people.

As someone responsible for safe, compliant structures, this is a major challenge because substandard steel often looks identical to quality materials. Without a trusted supplier, you risk structural failures, costly rework, and legal liabilities. It forces you to spend more time on inspections, verify certifications, and guard your project against unsafe materials.

Supply Chain and Logistics

You already work under tight timelines, but the country’s fragmented logistics system makes steel procurement even more challenging. Congested ports, inconsistent inter-island shipping schedules, and high transportation costs can delay your deliveries, sometimes by weeks.

For contractors and developers handling multiple projects, even a short delay can disrupt sequencing, increase labor costs, or force you to push back milestone dates. When steel doesn’t arrive on time, equipment sits idle, crews get rescheduled, and your overall productivity drops. A weak supply chain also means you can’t always secure backup suppliers quickly, leaving your project vulnerable to downtime.

Standards and Workforce

Maintaining quality standards becomes a bigger challenge when the local talent pool keeps shrinking. Based on the 2023 Survey on Overseas Filipinos by the Philippine Statistics Authority, an estimated 2.16 million skilled Filipino workers are working abroad.

With so many experienced workers choosing overseas opportunities, you’re left with fewer qualified professionals to assemble, weld, and inspect steel structures. Even if you secure high-quality materials, poor workmanship can still compromise structural integrity.

Impact of These Challenges on Construction and Infrastructure Projects

Here are the impacts of the challenges mentioned, showing how they can significantly disrupt construction and infrastructure projects.

- Delayed Timelines: Project completion is slowed by supply shortages, labor gaps, and logistical bottlenecks, disrupting schedules and overall productivity.

- Increased Project Costs: Rising material prices, equipment delays, and the need for alternative solutions drive up expenses for contractors.

- Risk of Substandard Materials: Limited supply and high demand may lead to sourcing from unverified suppliers, increasing the risk of poor-quality steel compromising safety and durability.

Why Regan Steel Remains a Strong Partner Amid Industry Challenges

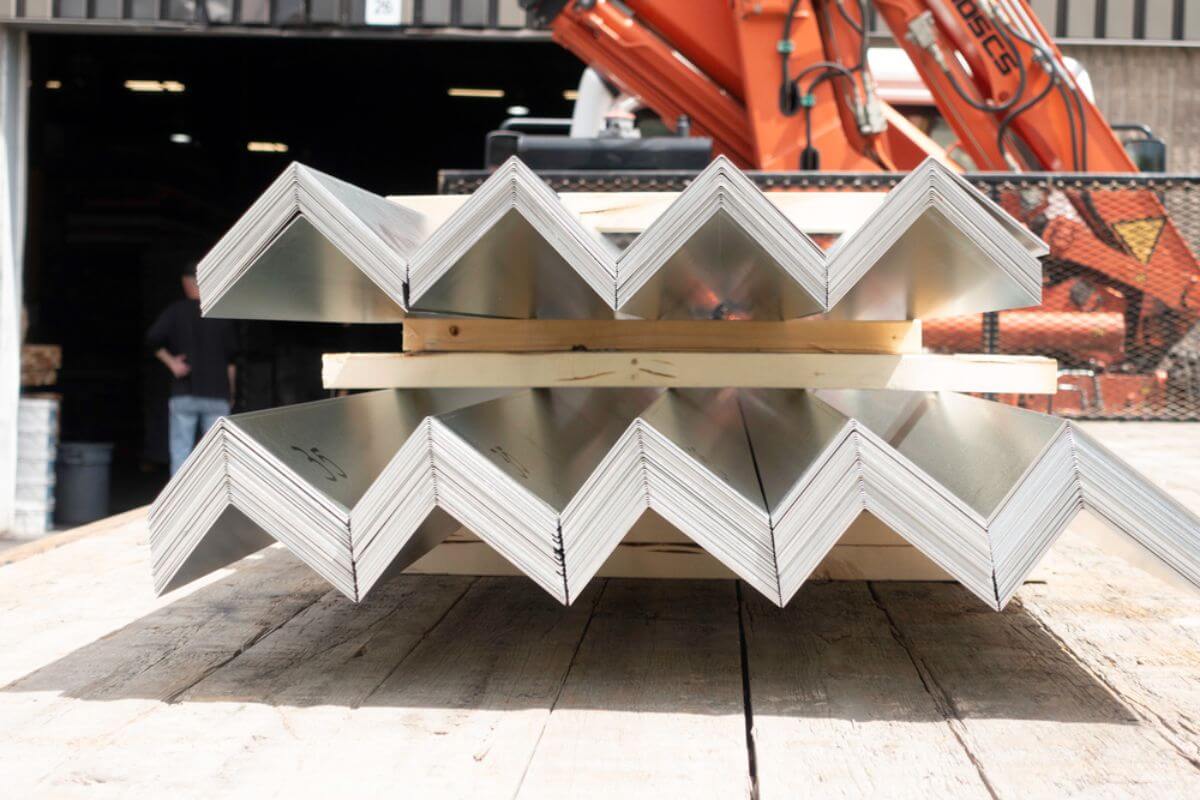

Regan Steel stands out for reliability, commitment, and a comprehensive product range. We deliver high-quality steel on time, ensuring project schedules stay on track despite market challenges.

Every beam, bar, and sheet meets strict engineering standards, ensuring safe and durable structures. Our wide selection streamlines procurement, reduces risk, and fulfills all project requirements.

Key Takeaway

The challenges facing the steel industry in the Philippines highlight how complex and fast-evolving the sector has become, especially with rising demand, global competition, and regulatory pressures. While these obstacles can influence construction, infrastructure, and industrial activities, they also create opportunities for innovation, stronger partnerships, and smarter sourcing decisions.

Partnering with Regan Steel means working with a supplier that stays strong even when the industry faces uncertainty. Our commitment to reliability, quality, and a wide selection of steel products ensures your projects remain on time, on budget, and built to last. Contact us now and let us deliver the strength your business needs, every step of the way.