What are the benefits of wide flange beams?

- Enhanced weight distribution

- Improved efficiency

- Standard sizing

- Suitable for many applications

When coming up with a structural project with your contractors and suppliers, the most common material that may pop up during the planning stage is the wide flange beam. If this is one of your first projects, then you might not be familiar with what the benefits of wide flanges are.

Amongst all the l-beams and structural sections you can use, most contractors and suppliers will recommend using wide flange beams — and for good reason! Their design and mechanical properties make it one of the most advantageous materials out there.

Want to learn more about this metal product? If you’re unsure about whether or not your project needs them, read on! In this article, we cover all the possible benefits of using wide flange beams in your project so you can have more confidence in this material.

What are Wide Flange Beams?

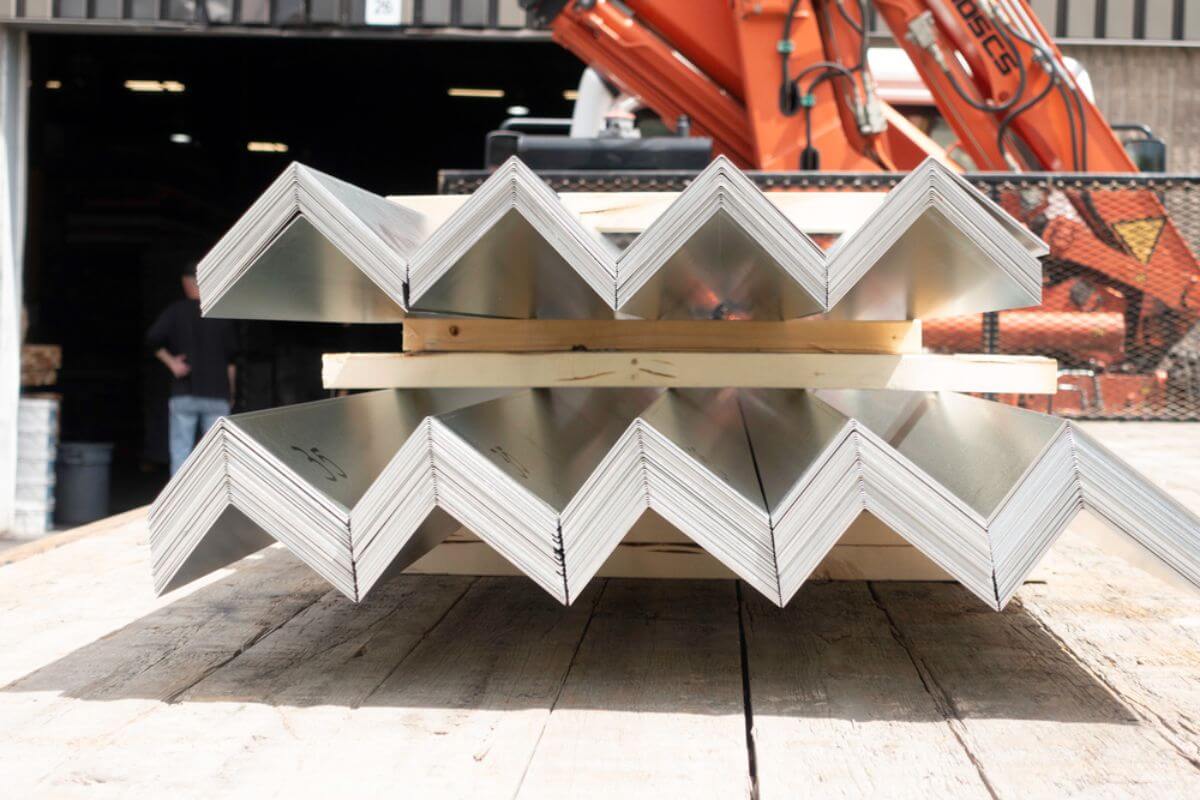

A wide flange beam — a type of l-beam — is a building material used in creating structures. Like the standard l-beam, a wide flange beam’s profile is similar to the letter “I” and “H.”

It has two parallel end units, which are completely flat and smooth — these are called “flanges.” The two flanges are connected by a central metal rod, called a “web.” This structure is what gives it that I and H shape.

While the flanges in a standard structural beam are narrow, those in a wide beam are much broader — hence their name. Their length can be equal to the height of the connecting web.

What are the Benefits of Wide Flange Beams?

There are many advantages to using wide flange beams in your project, such as:

Enhanced Weight Distribution

In construction, one of the biggest concerns is how your structure will evenly and effectively distribute weight — as too much in one area will cause the structure to buckle or break. This is especially important in ensuring structures are built to safely resist all factors that they are likely to face during their service life while remaining fit for use.

Wide flange beams are extremely efficient at disperse weight load over a larger area — thanks to their wider profile. This allows your team to feasibly design and build larger and wider structures without the risk of failure.

Plus, wide flange beams are typically made of one of the sturdiest materials available — rolled steel. This allows it to hold up larger and heavier loads without breaking.

Improved Efficiency

Another benefit of using wide flange beams is the weight and shape of the beam itself. When compared to other beam profiles of the same size, wide flange beams come out as the more efficient option due to their lighter weight.

Additionally, they use less metal material to make when compared to other options. Making wide flange beams is economical, and takes less construction time. Combine that with their improved weight resistance and distribution, this type of beam is a highly efficient part.

When it comes to the materials used to make these types of beams, they also provide significant cost-efficiency. Steel and aluminum are the metals of choice, both of which have the benefits of economy, strength, availability, and machinability behind them. Plus, steel wide flange beams are better equipped to resist the elements and hazards like fires — all while maintaining structural integrity.

Standard Sizing

All wide flange beams follow a standardized size chart, which helps architects, builders, engineers, and manufacturers to easily relay what sizes and weights are needed for a given project. Effective communication ensures that there is less risk of sizing issues, which can delay your project.

The standardized size chart is based on the sizes developed by the American Society for Testing and Materials (ASTM) International. Other countries commonly follow these standards, which helps in communicating with foreign project partners.

The size — denoted by a “W” — is measured based on the depth of the web, while the beam’s width is measured based on the length of the flange. Weight is described in pounds per foot. So, a wide flange beam on a metal catalog may be marked W12x26, meaning it has a 12-inch web depth and a weight of 26 pounds per foot.

Suitable for Many Applications

This type of beam is considered a “universal member” — which means it can be used in most structures. Because of its simple shape and efficiency, it’s considered a standard material for most structures. Plus, it is highly compatible with other primary and secondary structural materials.

This usability allows it to fit into many applications, such as:

- Temporary structures — wide flange beams can be used to create support beams, which hold back earth while walls, bridges, foundations, and other structures are built.

- Structural foundations — they can also be used to support and stabilize structures as either bracing, frames, or platforms. These can be found on homes, bridges, buildings, parks, and more.

- Retention walls — they also serve as a stabilizing structure to create walls like sound barriers along highways, walls within a basement, and more.

Key Takeaway

Now that we’ve covered the fundamentals and benefits of wide flanges, you may feel that it is something you could use for your project.

If you’re considering ordering wide flange beams for your application, you may be wondering where to find high-quality materials that will ensure stability and durability — in that case, contact Regan Industrial Sales, Inc. today! We are the most reputable steel manufacturer in the Philippines with over 50 years of service experience. We proudly supply top-grade structural steel products like wide flange beams for a variety of projects and would be happy to assist you in your project.