What are the cost factors for steel buildings?

- Manufacturer availability

- Raw steel price fluctuations

- Proximity to materials

- Building size

- Building type

- Design complexity

- Construction labor

A question we get a lot is: “How much do steel buildings cost?” But this question is tricky to answer, as the cost of any steel building follows no standard price list. In reality, there are several cost factors of a steel building to take into account.

These factors can vary and change from one week to the next, so coming up with an estimated price for your steel construction project can take some time to determine. If you’re a first-time buyer, here are the things to consider to help us produce an accurate quote for your steel building:

Manufacturer availability

Your construction project will depend largely on your steel product manufacturer. If you’re working with a design firm, then they’ll likely work with several partners, who’ll come up with proposals and prices. These can be influenced by many things, such as your required turnaround time, current production level, the design of your building, and so on.

If there are many manufacturers available, then you’ll be able to get more offers, which helps in getting more competitive prices. But, if you’re in a rush and need quality products quickly, then you might need to choose a manufacturer who can deliver a steel building fastest — which tends to be priced a bit higher than the lower bids. It all rests on your project’s needs, and your manufacturer’s availability and capabilities.

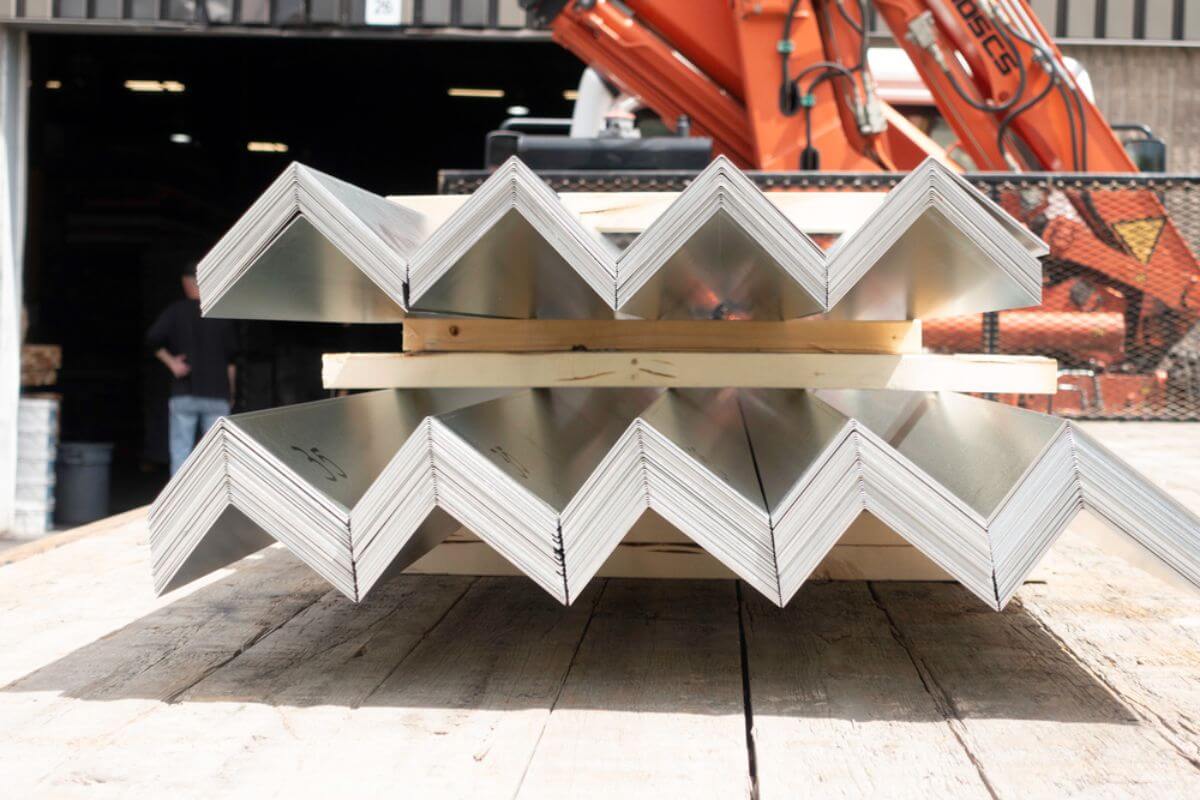

Raw steel price fluctuations

One of the biggest cost factors for any steel project stems from the raw materials themselves. The nature of the steel industry is always volatile — there’s no way to know exactly what prices raw steel will have on the day you need to order them because the price will always be fluctuating.

Steel is a global commodity that is subject to sudden price changes, due to several external factors. This includes the world economy, the value of your currency, and unpredictable weather. All of these factors mean its price can change at a moment’s notice.

With all that said, the building you’re planning on making might be within your budget now — but might go over it the next.

Proximity to materials

The distance your steel and steel products will have to travel from the manufacturer to your job site is another thing we have to consider. In some cases, your manufacturer may be located far from your building site, so higher transportation costs are unavoidable. Some delays in transportation are also likely if your manufacturer is far, which can put a strain on your labor expenses and project timeline.

Building size

Of course, the number of steel materials and products your project needs will affect its overall price. The more you need, the more considering its impact is on your building quote. Simply put, the bigger your building design is, the higher the cost will be.

Building type

Nowadays, there are plenty of options for making a steel frame building — some manufacturers even offer custom steel kits to provide customers with different building formats. You can use these to quickly create office buildings, residential spaces, garages, and more.

That said, using these pre-set frame designs can help you reduce your building costs somewhat. This is because they are easier designs to manufacture, and are made to be quickly assembled and erected. These frames are made to bolt together, and can even be ordered with a predetermined number of openings, such as windows, doors, and others.

These steel frames are made to quickly be produced, assembled, and erected — all of which make your project more material and labor efficient.

Design complexity

In their simplest, bare-bones form, steel buildings typically consist of a frame, roof, and walls. But, that doesn’t mean your building has to stop there — the kinds of designs you can achieve with this material are endless. But, as your design complexity increases, so does your building’s cost.

Using extra features, such as skylights, mezzanine levels, exterior cladding, lean-tos, frame-outs, and others can cause your steel building price to increase. This is because these customizations will require extra manufacturing efforts and resources, which increases the overall cost. Any last-minute design changes to your building will also cost you a substantial amount in manufacturing and labor.

Likewise, you should also consider the use of the building you’re making. Depending on its intended use, your design can be very simple, or extremely complex. For example, a steel-frame garage is easy to make and will cost less than an elaborate hotel or distillery.

Construction labor

Someone has to assemble the steel frame and products your building is using. While some manufacturers also provide erection services for the projects they’re working for, others may require a third party to complete the job.

There are many different costs to working with a separate construction crew. They’re also more likely to make errors during construction, which increases labor costs due to longer construction times. It may also lead to project delays and even lower build quality overall.

Union labor, demand, the time of year, and your proximity to suppliers are also factors that can influence the price of your construction labor.

Key Takeaway

If you’re ready to start your project, make sure to consider all of the steel building cost factors, which will help your partners make an accurate quote. To get the best quote, and the most bang for your buck, you’ll need to work with an experienced and reputable manufacturer.

Need help? Regan Industrial Sales, Inc. is here to guide you through your steel building project. We offer all the steel solutions you need for a successful build — from design to production. Contact us today to learn more!