Overview

- The choice between square and rectangular tubes significantly affects structural integrity, cost, and aesthetics.

- Steel tubes are crucial in construction for their strength-to-weight ratio, corrosion resistance, and ease of fabrication. The demand is projected to reach $92.8 billion by 2032.

- Square tubes have equal-length sides and strong integrity for frames and equipment, while rectangular tubes, with varying sides, excel in beams and machinery.

Choosing the right steel frame for your construction project is a critical decision that can significantly impact the structural integrity, cost, and overall aesthetics of your building.

Two popular options in the construction industry are square and rectangular tubes. While both offer exceptional strength and durability, they have distinct characteristics and applications.

In this article, we will know the key differences between square vs rectangular tubes, exploring their advantages, disadvantages, and ideal use cases. By the end of this article, you will have a clear understanding of which steel frame is the perfect fit for your specific construction needs.

Understanding Steel Tubes

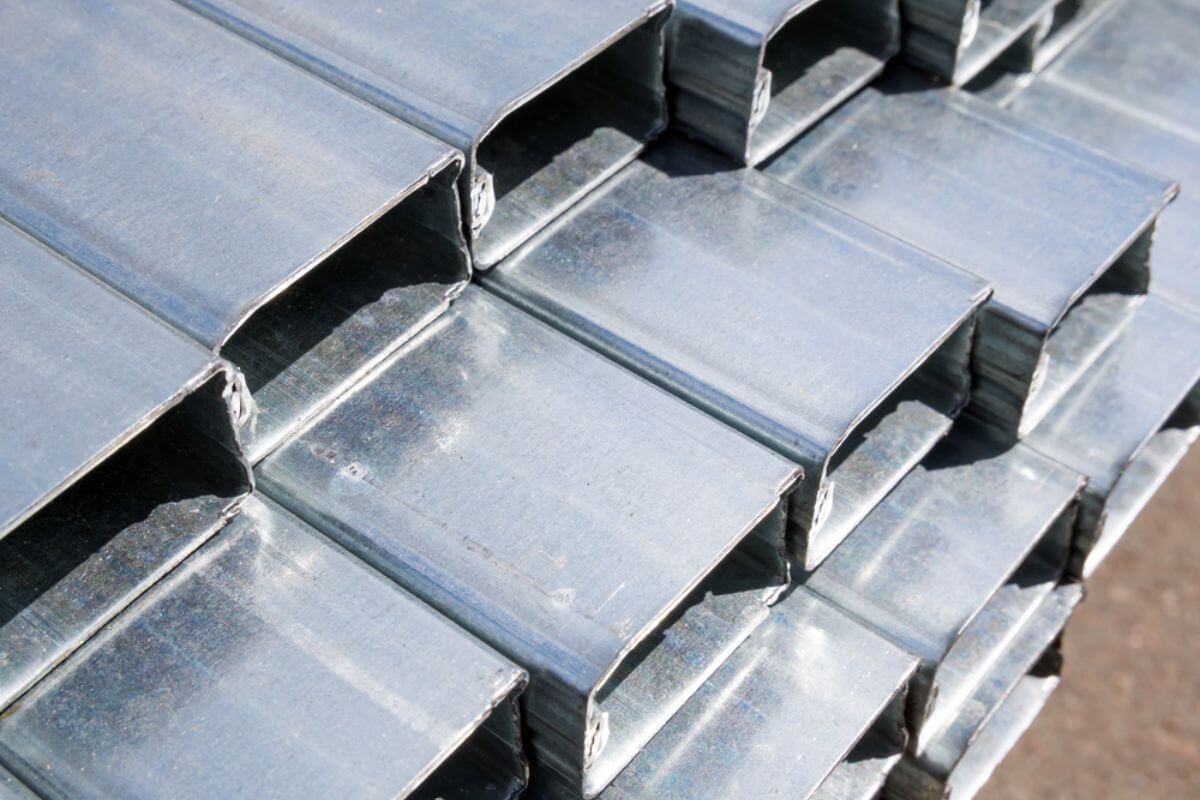

Steel tubes are vital in construction, and used for frames, supports, railings, and scaffolding due to their high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are essential for building durable structures that endure heavy loads and environmental conditions.

The demand for steel tubes is expected to hit $92.8 billion by 2032, fueled by urbanization and infrastructure growth. We will be focusing on the features and applications of square and rectangular steel tubes, moving beyond the conventional cylindrical design.

What are Square Tubes?

Square tubes feature a cross-section with equal-length sides, offering both symmetrical aesthetics and strong structural integrity. They are valued for their load-bearing capacity and visual appeal. Typical uses include building frames, columns, furniture, machinery, and sports equipment.

What are Rectangular Tubes?

Rectangular tubes feature a rectangular cross-section with varying longer and shorter sides. Its shape makes it ideal for applications where loads predominantly come from one direction, such as beams and trusses. Rectangular tubes are widely used in automotive manufacturing and machinery production.

What Are the Key Differences Between Square and Rectangular Tubes?

In 2022, the building and infrastructure sectors utilized 52% of global steel production, while the automotive industry accounted for 12%. These figures frame our exploration of how square and rectangular tubes serve distinct roles in industrial and construction applications.

Structural Properties

Square tubes distribute strength evenly in all directions, making them versatile for applications with varied load angles, ensuring strong support without compromising integrity. This quality is essential in construction and engineering, where stability and reliability are important.

Rectangular tubes excel in applications where resistance along their longer sides is critical, such as in beams and columns. Their shape naturally enhances load-bearing capacity in one primary direction, making them the best choice for projects that demand structural performance and enduring strength.

Weight and Material Efficiency

Rectangular tubes generally offer comparable structural integrity with less material compared to square tubes. This efficiency in material usage can lead to reduced weight and lower costs in construction projects.

In contrast, rectangular tubes offer a more efficient use of steel, achieving comparable strength levels with less material. This translates to cost savings on both the steel itself and potential reductions in transportation and installation expenses due to the lighter weight of the structures.

Fabrication and Installation Process

Square tubes offer easier cutting and welding thanks to their uniform shape, which streamlines manufacturing processes. Their symmetry also simplifies alignment and installation, improving maneuverability and stability during setup.

Contrarily, rectangular tubes can present fabrication challenges due to their different dimensions. These variations may necessitate specialized equipment and techniques, such as custom cutting tools or specific welding methods, to ensure precise assembly.

Despite these differences, square and rectangular tubes can be effectively fabricated and installed with the right tools and expertise. Skilled professionals can handle various tube shapes and sizes, adapting their techniques to achieve the best results in construction and industrial applications.

Cost Considerations

While square tubes often have higher initial material costs due to their greater material usage, their straightforward fabrication process can mitigate labor expenses, potentially resulting in overall cost savings.

Conversely, while rectangular tubes may save on material costs due to their efficiency, the complexity of their fabrication process can lead to higher labor costs. Balancing these factors involves evaluating both upfront expenses and long-term benefits.

Which Steel Frame Works Best for Your Project?

Ultimately, deciding between square and rectangular steel tubes for your construction project relies on your project’s unique needs and limitations. Evaluating the advantages and considerations of each option enables you to make a well-informed choice that contributes to the success of your construction project.

Key Takeaway

Whether prioritizing the uniform strength and straightforward fabrication of square tubes or the design flexibility and load-bearing capability of rectangular tubes, the decision between square vs rectangular tubes should align with your project goals and requirements.

Looking to secure top-notch steel tubes for your construction or industrial projects? Regan Steel got you! Trust our expertise and unwavering commitment to quality to support your projects seamlessly from start to finish. Contact us today to get started.