What are design mistakes to avoid in sheet metal parts?

- Having a Tight Bend Radius

- Making Excess Holes

- Not Including Hardware Specs

- Using The Wrong Metals

- Picking The Wrong Finish

- Being Unaware of Machine Capabilities

The best practice with making sheet metal designs is to engineer first, then build later. A good and well-thought-out design can save plenty of time and money for you, and make metal fabrication all the more productive for your service provider.

When making your designs, it’s crucial to know the common mistakes that less experienced clients make. Consider these design mistakes to avoid in sheet metal parts to know what pitfalls to avoid, and how to improve your current plans to be more feasible for your manufacturer.

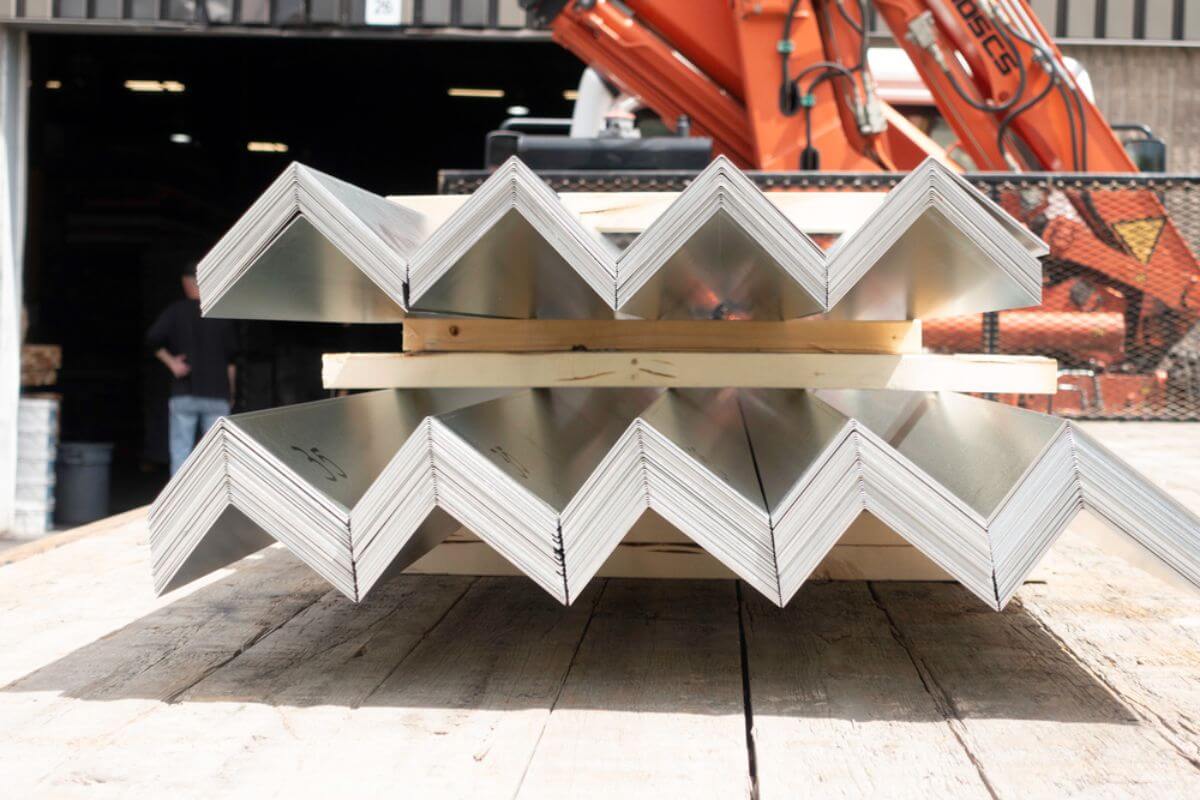

Having a Tight Bend Radius

When you bend sheet metal during the fabrication process, the resulting bend isn’t a perfect 90° angle. Instead, the bend has a slight curve. If you measure the length of that bend and divide it by two, you’ll get the bend radius.

The bend radius is something to consider when drawing up your design. This is because when the bend radius is made too tight, then it becomes a weak point in the sheet metal. Having a near-perpendicular bend area will cause your part to break easily. It can also cause a deformity in the dimensions of the metal part you’re trying to create.

Make sure to understand the bend ratios of the metal you’re using. The harder and thicker the metal, the greater the minimum bend radius. If you’re unaware of this quality, then cracks in the metal are likely. These cracks will mean your parts have to be redesigned and re-fabricated — increasing production waste and costs.

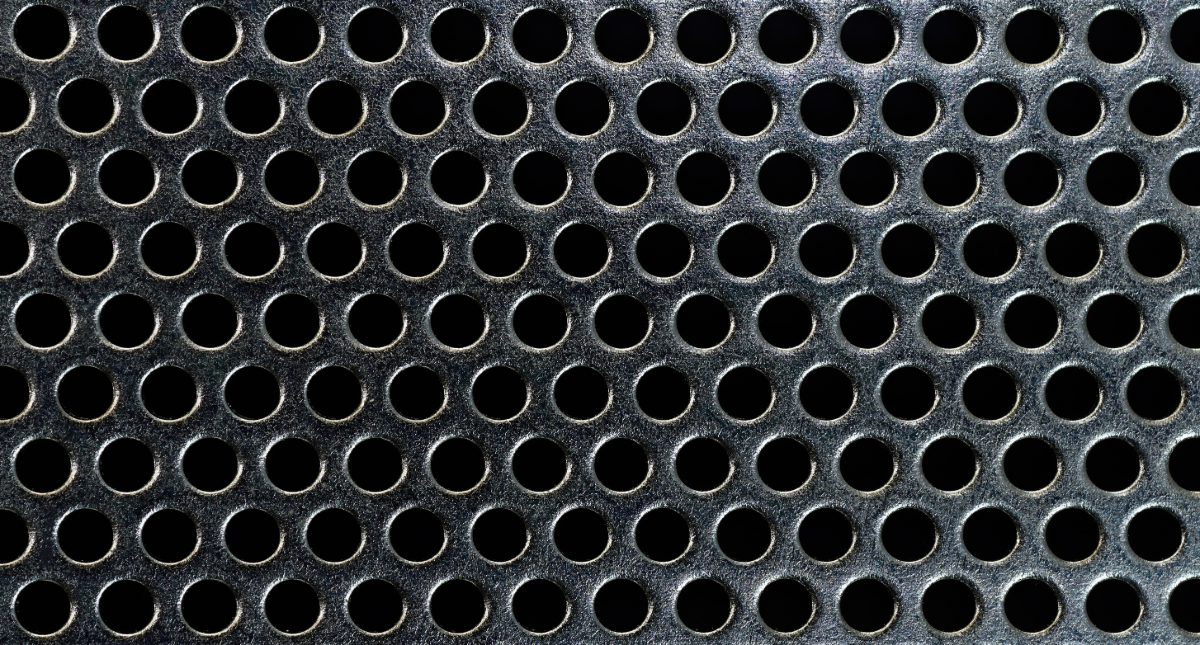

Making Excess Holes

Your sheet metal can only handle so many cuts into its surface. These design aspects should only be included only when necessary. Holes in particular are difficult to add in large quantities. This is because they add complexity to the process, and each hole has a significant chance to break the sheet metal.

Additionally, placing these notches and other features too close to your bent edges can affect the function of the sheet metal part. For instance, if holes are placed near a bend radius, they may lose their capacity to hold hardware or withstand tension. The best practice here is to not place any cut features near any bends. If you really need to add one near a bend, try to add them past the bend line.

Not Including Hardware Specs

Including all details — even the tiniest ones — is important when compiling your hardware specifications in your CAD (computer-aided design) file. The CAD files are digital blueprints for 3D and 2D designs that include information on materials, processes, and other data on the design. Every sheet metal fabrication process begins with a CAD file.

Without the proper hardware specifications, you will end up having long lead times for your fabrication. You should note which types of nuts, studs, bolts, and other components you want your product to have. With a comprehensive CAD file, you will get exactly what you want and in less time.

Using The Wrong Metals

Selecting the right materials for your project is very important. When in the designing stage, already consider the type of environment your product will be facing daily. If you design based on mechanical properties alone, your product may end up becoming unusable in a short amount of time. For example, untreated steel would not last very long in a high-salt, damp environment. Avoid increased manufacturing costs by considering some of these factors:

- Resistance to heat, corrosion, and other environmental factors

- Conductivity of electricity and heat

- Mechanical features like tensile strength or malleability

- Toughness and wear resistance

- Weight

- Manufacturability

- Cosmetic look

Picking The Wrong Finish

Aside from the base materials, the sheet metal finish also serves an important purpose for your final product. Some finishes protect steel, while others add cosmetic features to their surface.

Aesthetic finishes usually don’t provide any corrosion protection — but powder coating does offer some protection against water and other elements. Chemical finishes alter the properties of the steel surface or add additional elements to make it more corrosion resistant. When choosing a finish, there are many options to consider. So, check which one will give results that best suit your part.

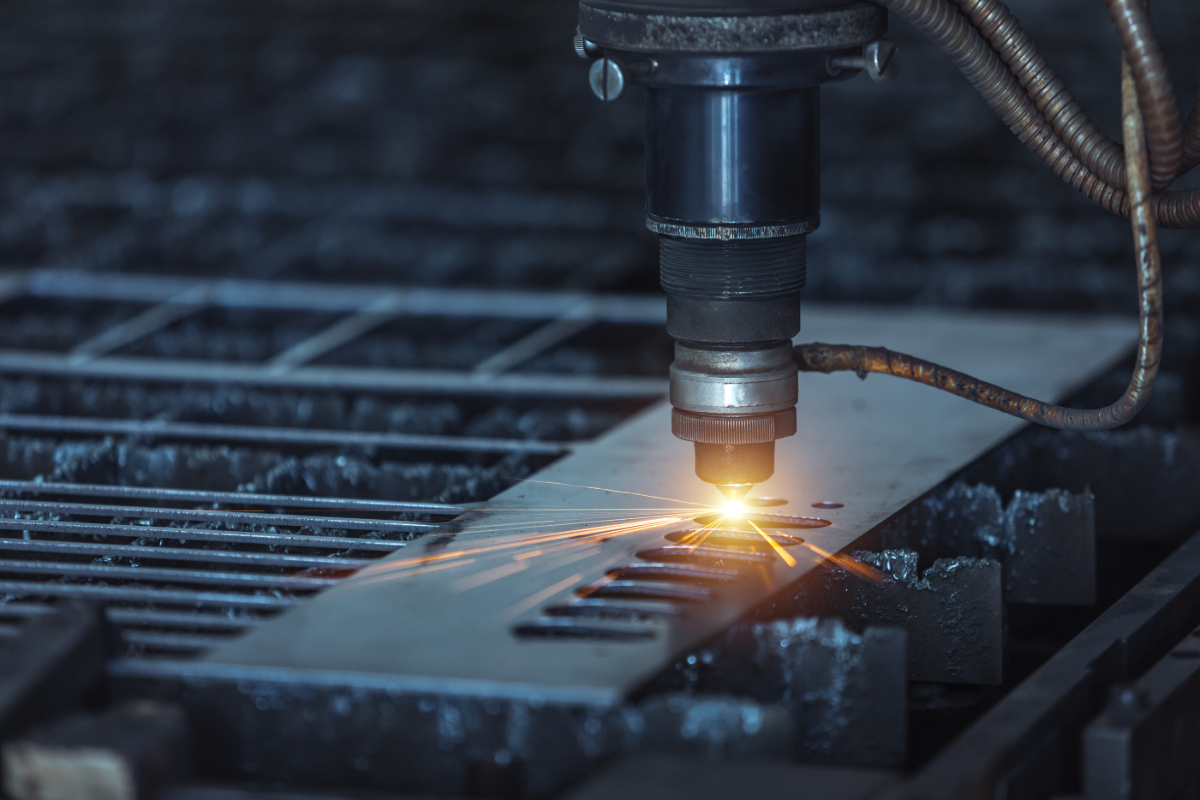

Being Unaware of Machine Capabilities

Another common mistake when designing sheet metal parts for manufacturing is a general lack of knowledge of the machines you intend to use. When speaking with a manufacturer, take the time to ask them about their machines and their capabilities early on. You can try asking for a guided tour around their facility. This allows you to make the appropriate adjustments to your design to better meet these constraints.

Large sheet metal brake machines can make wider bends in your sheet metal. The presence of CNC machines shows how precise the parts may be. These vary drastically — one manufacturer may be able to provide certain services, while another won’t. So it’s important to keep their machine capabilities in mind when drawing up your production plans.

Key Takeaway

It’s useful to keep these design mistakes to avoid in sheet metal parts in mind before you start any manufacturing design. That being said, many of these tips point to one thing: knowledge is key. It’s crucial to do plenty of research when creating your part designs.

Pairing with a manufacturer with years of experience and honed skills can help you make drastic but much-needed changes to your sheet metal part design. Consult with Regan Industrial Sales Inc. today and learn more about sheet metal fabrication, and the ways that we can add value to your design.