Overview

This article explains the differences between I-beams and other steel shapes, highlighting their strengths, limitations, and ideal applications.

It guides readers on selecting the right steel section based on load type, span length, installation needs, and budget, emphasizing informed decision-making for efficient, durable structural design.

I-beams, also known as universal beams, are structural steel sections designed to carry heavy loads over long spans, making them widely used in bridges, building frameworks, and industrial structures.

However, I-beams are only one of several steel shapes available. Other profiles, such as channels, angles, and square tubes, offer different structural advantages depending on design and load requirements. Comparing these options helps determine the most suitable steel section for a project.

In this article, we will compare I-beams versus other steel shapes to help you understand their unique advantages and best applications. At Regan Steel, we offer a wide variety of steel shapes to suit every project requirement.

Comparing I-beams Versus Other Steel Shapes

| Steel Shape | Description | Strenghts | Weaknesses | Best for |

|---|---|---|---|---|

| I-beams | A single-piece, hot-rolled steel section with a web and flanges that taper toward the center. | Strong in shear and flexure in one direction; efficient for carrying loads across a span | Weaker in bending along the X-X axis; limited size options due to manufacturing constraints. | Girders, floor beams, and columns where loads are applied perpendicular to the web. |

| Wide Flange Beams | A type of H-beam with wider and longer flanges, resembling the letter “H” more closely. | Excellent strength-to-weight ratio; handles larger loads because of wider flanges. | Heavier and may cost more than standard I-beams. | Buildings, bridges, and applications require high load-bearing capacity and stability. |

| H Beams | Steel beams with an “H”-shaped cross-section and thicker webs and flanges. | More stable and stronger than I-beams; ideal for heavy axial, flexural, and torsional loads. | Heavier and less efficient when weight reduction is a priority. | Heavy-duty columns, large industrial structures, and high-load applications. |

| C Channels | U-shaped sections with a web and two flanges. | Lightweight, economical, and easy to handle or install. | Not ideal for multi-directional loads; weaker in torsion and lateral bending. | Roof framing, joists, supports, and cost-sensitive projects. |

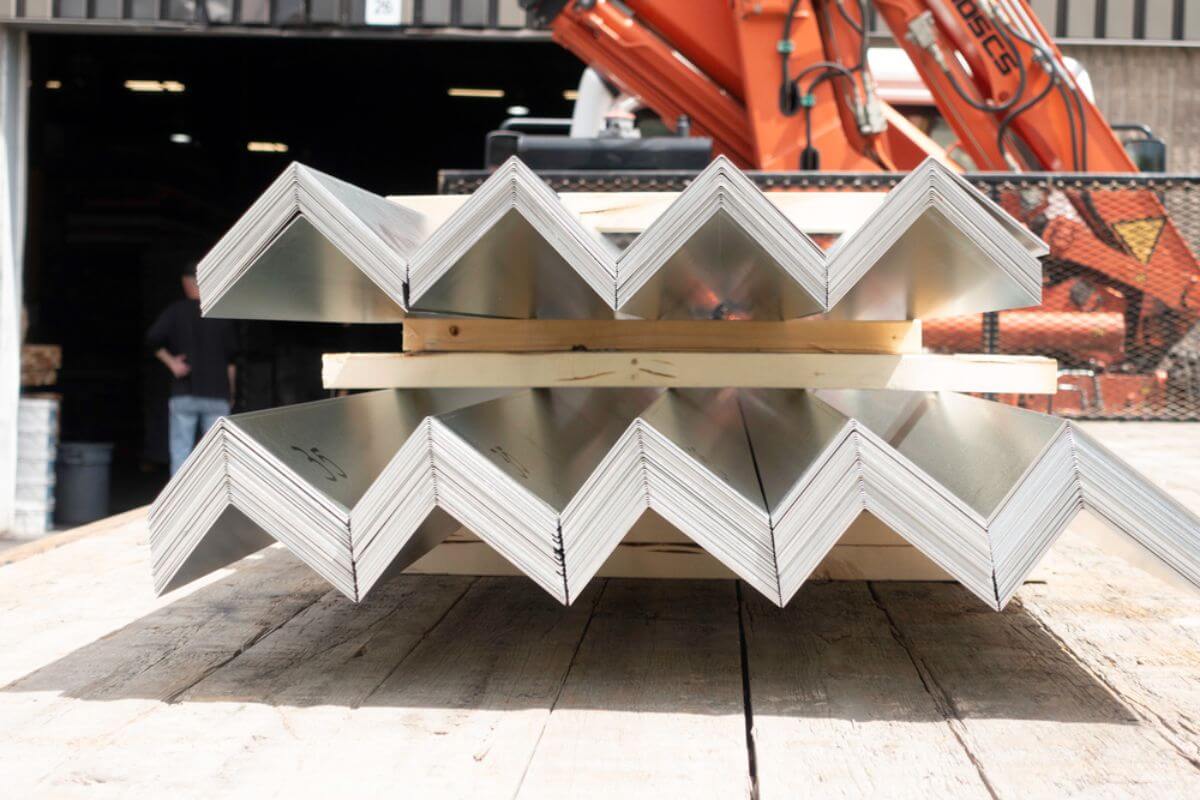

| Angle Steel | L-shaped beams with two flanges meeting at a 90-degree angle. | Great for bracing and connecting structural elements. | Poor performance in spanning applications; weak in bending and torsion. | Bracing, connections, framing reinforcement, not for long spans. |

How to Choose the Right Shape for Your Project

Here are some ways to choose the most suitable steel shape for your structural needs.

Identify the Type and Direction of the Load

Start by determining how the load will act on your structure, whether vertically, horizontally, or from multiple directions. This helps you match the steel shape to the forces it must resist.

For example, I-beams are ideal for loads applied perpendicular to the web, while H-beams perform better under heavy axial and torsional loads. Analyze whether the load is concentrated, distributed, or changing over time.

Consider the Required Span Length

The longer the span, the stronger and stiffer your beam needs to be. You can start by measuring the distance your steel member must cover without support, then compare that with the structural capacity of different shapes.

Wide flange beams and H-beams excel at long spans due to their flange width and stiffness. Shorter spans may allow for lighter options like C-channels or angle steel. Choosing based on span length helps you avoid deflection, sagging, and vibration issues.

Evaluate Weight Versus Strength Needs

Heavier shapes like H-beams provide exceptional load-bearing capacity but may require larger equipment and increase installation costs. Lighter options, such as C-channels, are easier to work with but may not support multi-directional loads.

Assess your structural priorities. Do you need maximum strength, reduced weight, or an efficient middle ground? This helps prevent overdesigning your project or selecting a shape that cannot withstand long-term stress.

Match the Shape to Installation and Connection Requirements

If your project needs multiple connection points, wider flanges from W-beams or H-beams offer more stability and easier bolting or welding. For lighter framing where speed matters, C-channels or angle steel may be more practical due to their simpler profiles.

Evaluate your site conditions, available tools, and the skill level of your installation team. Matching the shape to your connection needs ensures faster assembly, stronger joints, and reduced risk of installation errors, all contributing to a more efficient and reliable project.

Factor in Budget and Availability

Some shapes may be ideal structurally but harder to source locally, which can delay your timeline and increase expenses. Standard I-beams, wide flange beams, and channels are often more affordable and widely stocked, while specialized shapes may cost more.

Compare prices, inquire about delivery schedules, and coordinate with your supplier early to avoid delays. Factoring budget and availability ensures that you choose a shape that not only meets engineering requirements but also aligns with your project timeline and financial targets.

When to Choose I-beams?

Choose I-beams when a structure requires strong load-bearing capacity over long spans. Their shape provides excellent bending resistance and efficiently handles primarily vertical loads while minimizing material use. I-beams are ideal for applications that require clear, open spaces without intermediate supports, such as large floor areas, wide roof spans, and industrial or commercial structures.

Key Takeaway

When comparing I-beams versus other steel shapes, it’s clear that I-beams excel in applications requiring high bending strength and long-span support, while other shapes like channels or angles may be better suited for lighter loads or specialized framing.

Choosing the right shape depends on load requirements, span length, and installation needs. For reliable, high-quality steel and expert guidance on selecting the perfect shape for your project, contact us now, and together let us build strong, durable structures.