How do you choose the best angle bar supplier in the Philippines?

- Check product quality and standards

- Review the range of sizes and specifications

- Confirm the supplier’s proven track record

- Compare competitive pricing and value

- Ensure availability and timely delivery

Overview

- Choosing the right angle bar supplier in the Philippines is crucial for project safety, durability, and efficiency.

- Key considerations include product quality, proper specifications, supplier track record, competitive pricing, and reliable delivery.

- Regan Steel offers high-quality angle bars, proven expertise, and dependable service to support successful construction and fabrication projects.

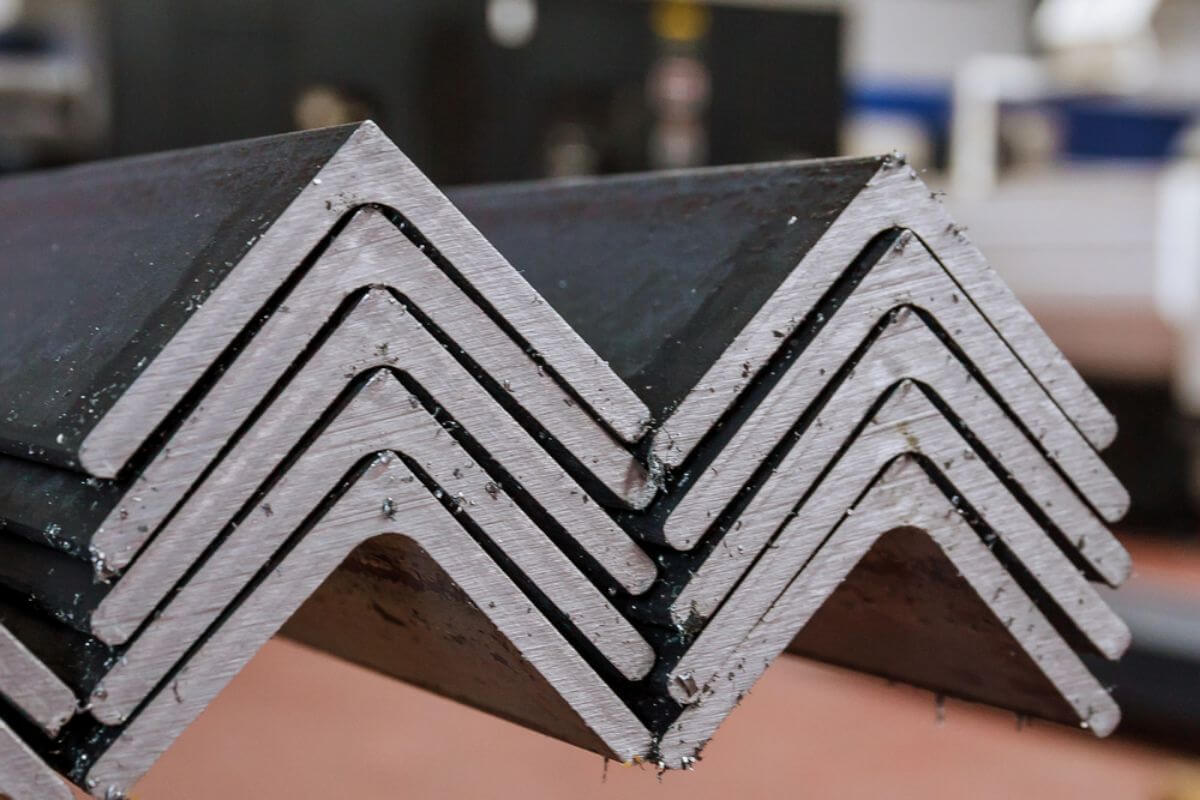

Among essential construction materials, angle bars are prized for their strength and versatility. They are widely used in building frameworks, support structures, shelving, and machinery, making them indispensable in construction, engineering, and fabrication.

When choosing the best angle bar supplier in the Philippines, reliability is key to ensuring project success and safety. Regan Steel, a trusted supplier of high-quality steel products, guides clients on selecting the right supplier and highlights the factors that guarantee long-term value and optimal results.

Check Product Quality and Standards

Angle bars are widely used in construction, manufacturing, and structural projects, so they must meet strict standards for strength, durability, and safety. Check for certifications such as ISO or PS (Philippine Standard) marks, request mill test reports, or inspect samples for uniform thickness, smooth edges, and absence of defects like cracks or rust.

It is also essential to confirm that the supplier follows proper fabrication and galvanizing processes, which directly influence corrosion resistance and long-term performance. Using substandard angle bars to cut costs can have serious consequences. Weak or poorly made steel may bend, crack, or fail under pressure, endangering workers and compromising the structural integrity of the project. In severe cases, this could threaten the lives of occupants or result in costly accidents.

Review the Range of Sizes and Specifications

Not all angle bars are the same. They come in various dimensions, thicknesses, and material grades to suit different construction and fabrication needs. For example, the size of the legs, the thickness of the steel, and the type of finish can vary depending on whether the angle bar will be used for structural framing, shelf supports, or heavy-duty applications.

You can start by identifying the exact size and specification needed for your project, such as the leg length, thickness, and steel grade. Then, compare this with what the supplier offers.

Using the correct size and specifications is important because mismatched angle bars can lead to structural weaknesses, poor fitment, and even potential safety hazards. The right size ensures the load is properly supported, while the right specification ensures durability, resistance to corrosion, and compliance with engineering standards.

Confirm the Supplier’s Proven Track Record

A supplier with a strong history in the industry often demonstrates a commitment to meeting client expectations, following industry standards, and maintaining business relationships. This history becomes an assurance that you’re dealing with a company that understands the demands of the Philippine construction market, from compliance with safety regulations to adapting to project deadlines.

You can determine if a supplier’s track record is proven by checking client testimonials, project portfolios, industry certifications, and the length of time they’ve been operating. Reputable suppliers often showcase past projects or provide references you can verify.

The connection between their track record and the quality of angle bars they offer lies in experience; if they have a history of excellence, they are more likely to source materials from trusted mills, maintain strict quality control, and invest in proper storage and handling to prevent damage or defects.

Compare Competitive Pricing And Value

Cheaper angle bars often compromise quality, leading to costly repairs or replacements. High-quality bars deliver superior performance, durability, and long-term savings.

To effectively compare competitive pricing and value, start by requesting detailed quotations from multiple suppliers. Look for transparency in their pricing breakdowns, including any additional costs such as delivery fees or customization charges.

Next, assess the quality of their products by reviewing specifications, certifications, and any warranties they offer. It’s also helpful to read customer reviews or request sample products to evaluate their workmanship.

Ensure Availability and Timely Delivery

Material delays can halt work, disrupt schedules, and increase costs. Reliable stock availability ensures projects stay on track. Verify suppliers’ inventory management, logistics, and delivery history, and confirm lead times, schedules, and contingency plans to avoid disruptions and meet deadlines efficiently.

Partnering with a supplier who can consistently provide on-time deliveries ensures that your construction work remains on schedule, reduces stress on your project team, and keeps your clients satisfied with the timely completion of their projects.

Key Takeaway

Choosing the best angle bar supplier in the Philippines means partnering with a reliable provider who ensures quality materials, competitive pricing, and timely delivery for smooth, uninterrupted project execution.

If you’re looking for a dependable partner in steel supply, Regan Steel is your go-to choice. With a proven track record in delivering high-quality angle bars and other steel products across the Philippines, we combine superior materials with unmatched service. Contact us today and experience the confidence of working with a supplier who delivers on time, every time.