What are the advantages of using structural steel for fabrication projects?

- Strength and durability

- Improved safety

- Lower costs

- Versatility

- Faster fabrication speed

- Environmentally safe

Today, structural steel is used in a wide variety of metal and fabrication applications. From fabricating equipment components to laying foundations for roads and bridges, to raising commercial buildings, structural steel can be found nearly everywhere. Its popularity is due to the many advantages of using structural steel for fabrication projects, which we enumerate in this article. Read on to learn more about structural steel, and how choosing this material can benefit your metal fabrication project.

What is Structural Steel?

This is a category of steel, usually used in forming construction materials and products. The most common structural steel pieces have long beam profiles such as an H-beam, though they can take nearly any form you desire. Structural steel is the popular choice for construction and fabrication for its many advantages, such as:

Strength and Durability

Strength and durability are perhaps two of the most important qualities metal materials should have. Especially if you’re in the business of creating new buildings or structures, you’ll want your metal materials to stand the test of time. Structural steel is perfect in this regard, as it is stronger than concrete, and can power through raging storms and other adverse weather conditions.

Structural steel also performs reliably against fire, earthquakes, and other natural disasters without losing strength or stability. This is a huge advantage for fabrication projects, as the less you have to worry about the strength of the material, the less you have to allocate for maintenance, replacement, and repair.

Improved Safety

Safety is another important factor in fabrication work. Choosing metals that are suitable for your application, yet are safe enough for people to handle, process, and work with is important for reducing the risk and failure of your project.

Most grades of structural steel are inert and have non-reactive properties. This means they have limited health, handling, and safety concerns compared to other metals. Additionally, this means structural steel does not quickly react to water or air, is resistant to mold and pests, and can be easily cleaned.

Lower Costs

Structural steel is generally one of the more cost-effective fabrication materials. Steel prices are more stable than other markets and remain at a steady, affordable price for manufacturers. This helps reduce cost, and its durability and longevity also contribute to a quicker return on investment.

Furthermore, structural steel tends to be lighter and more malleable than some other metals. This means your project may require fewer materials and labor to fulfill your fabrication objectives.

Versatility

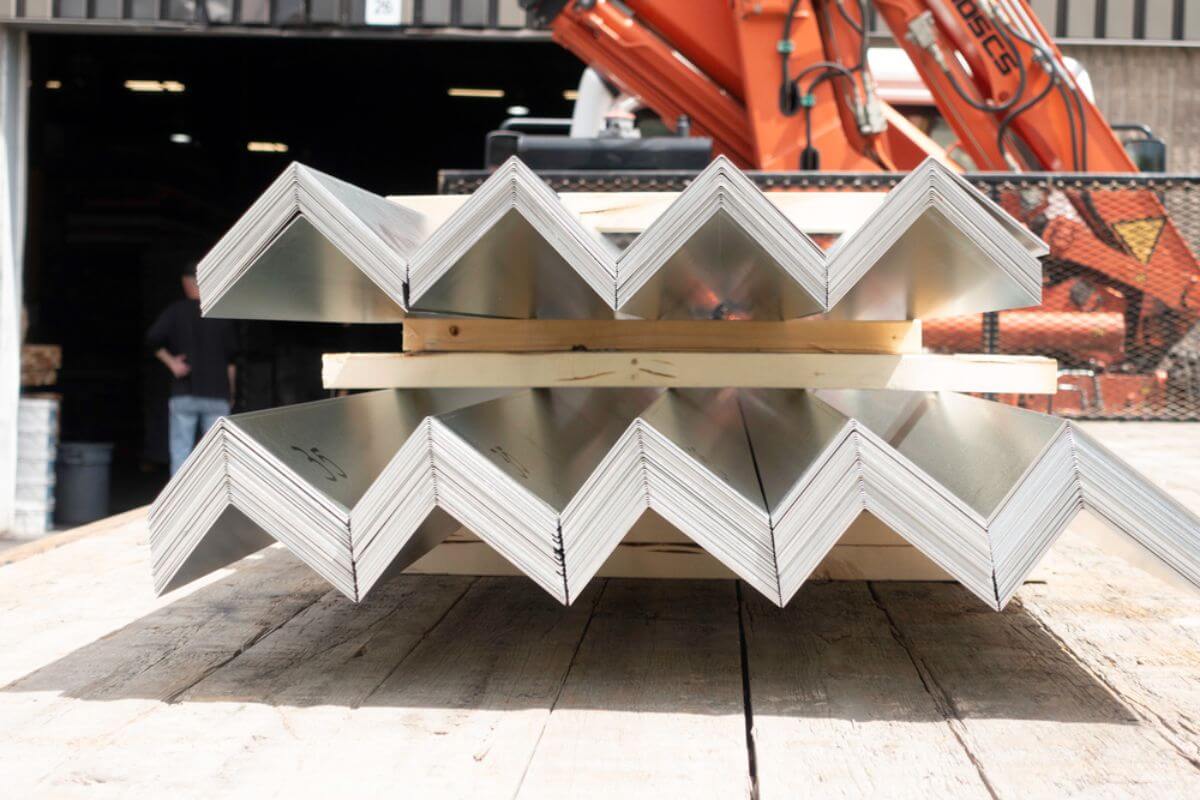

There are many structural steel products that you can fabricate for your project. Whether you need pieces for roofing, reinforcement, ventilation systems, electrical busways, or others, there are ways to form structural steel into a piece suited for the application.

For example, common structural steel products your project could use are compound beams, steel plates, tubes, pipes, reinforcing bars, and many more. You can also consult with your steel fabricator to come up with custom designs of your own.

Faster Fabrication Speed

Deadlines are hard to hit for any fabrication job. Targets have to be set and hit consistently throughout the entire project to avoid costly delays. Fabrication incidents like worksite hazards, poorly made products, and the like can make this even more difficult.

Luckily, structural steel is a material that has fast fabrication speed. As mentioned previously, it offers strength, durability, and safety that’s hard to beat. These advantages lead to a reduced likelihood of broken or unstable metal products. They also don’t take up too many resources to install, making it easier for workers to erect and assemble your fabricated pieces.

Environmentally Safe

Another concern for fabrication projects is sustainability. Structural steel has a low carbon effect and is recyclable. These characteristics mean that structural steel pieces can be salvaged and used again without losing quality or stability.

Furthermore, most modern steel plants have been reformed to be more energy-efficient and are capable of recycling most of the resources used to make structural steel. As a result, structural steel is a popular “green” choice for fabrication.

Structural steel is also a great material for blocking out environmental pollutants. When used in buildings and interior spaces, it prevents things like smog, dust, and smoke from entering, leading to a healthier space for everyone.

Key Takeaway

There are many advantages to using structural steel for fabrication projects — from mechanical properties to cost-effectiveness, to your environmental impact, it is difficult to find another metal material that can outperform structural steel in that regard.

Whether you need steel for architectural design, or commercial construction, or other similar applications, Regan Industrial Sales, Inc. offers a wide variety of steel products that are long-lasting, high-performance, and economical. We ensure that our structural steel products and fabrication services can best meet the needs of your project or business.

If you are interested in availing our products and services or would like more detailed information, contact us.