What are the advantages of steel tubing?

- Strength

- Precise outside diameter

- Different shapes

- Consistent measurements

- Telescoping

- Rigidity

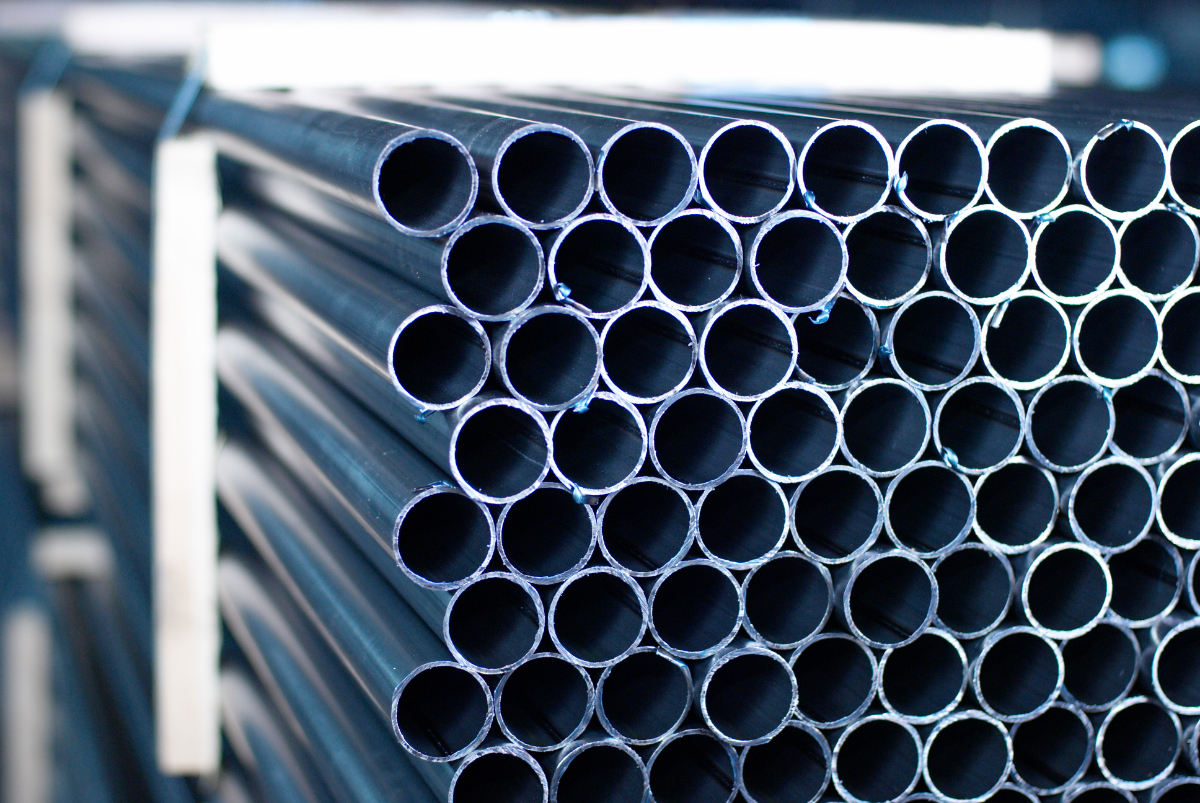

Steel tubing is a popular material that is used in many applications. Because they’re both made from steel and have similar uses, steel tubes and steel pipes can be confused. In some cases, the terms are used interchangeably. But there are clear differences, and there are some advantages of steel tubing that steel pipes do not have.

Both of these materials are very useful in their niches. Steel pipes are extensively utilized in construction projects, and steel tubing fits well into its applications. Here, we’ll delve deeper into the benefits of using steel tubing for your next project. Read on.

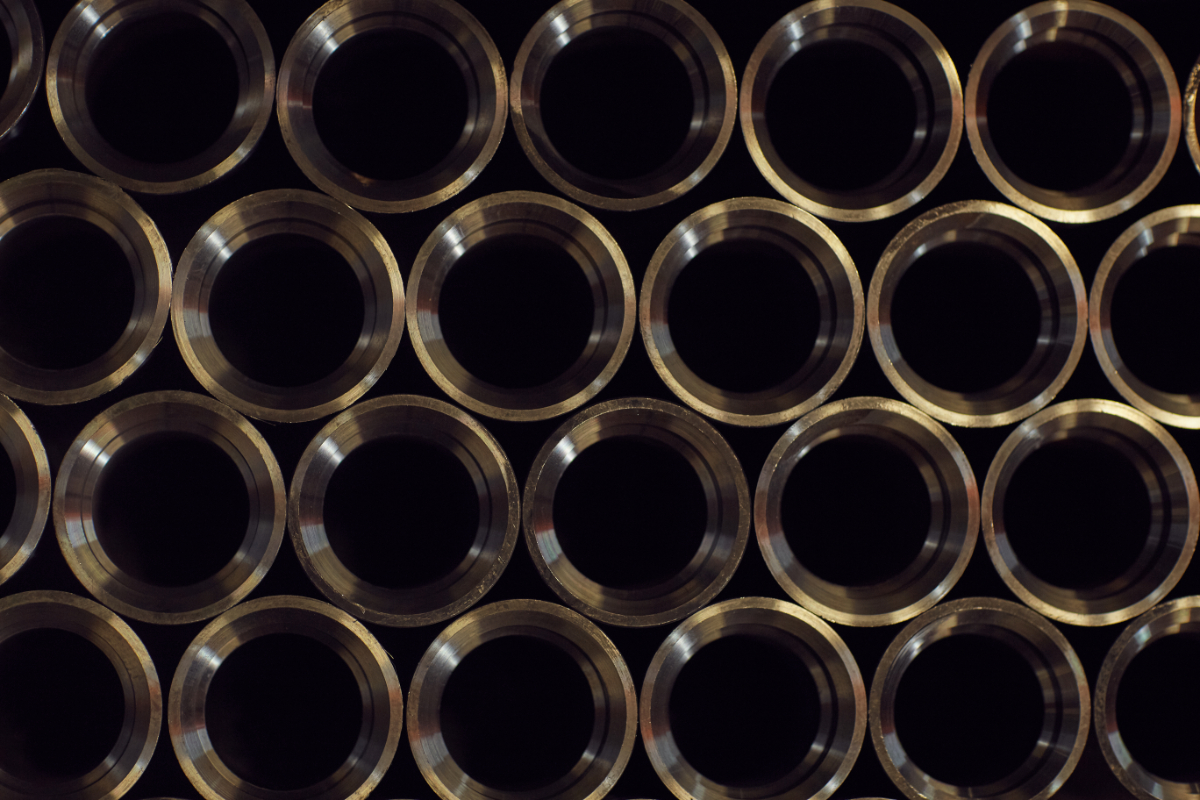

Strength

If your project requires stronger tubes, then using steel tubing is the right choice. It is no secret that steel is a naturally durable material, stronger than most other materials out there for pipes and tubes. It has a greater ability to resist corrosion and vibrations, shock, and pressure.

An added benefit is when they’re under extreme pressure, still, the tubing would bend instead of breaking. This means that when they fail to withstand the pressure, leaks will still be prevented. The strength of steel tubing relies on its wall thickness, so order thicker walls if durability is what you’re after. Knowing this, steel tubing is reliable enough for projects that require strength.

Precise Outside Diameters

One of the biggest differences between steel tubing and steel pipes is their applications. These applications dictate how they are made, ordered, and measured. Steel tubing is used for more structural applications. They don’t transport gas or water as steel pipes do, so they are measured by their outside diameter. They are ordered by outside diameter and wall thickness as it matters more that you know how much they can hold from the outside instead of the inside. Since steel tubing is commonly made for small diameters, this ensures that they fit well into the structure they’re made for.

A good example is medical equipment that need precise measurements for steel tubing. Projects that need specific measurements, especially if they’re smaller, would benefit from the use of steel tubing.

Different Shapes

The shape is the rule of thumb to quickly differentiate between pipes and tubes. This is also another advantage that steel tubings have — they come in different shapes. You can get round steel tubings, but you can also get them square or rectangular to fit your needs. If the tube is circular, the longitudinal pressure would be more evenly distributed. But sometimes, square or rectangular tubes are needed to fit the entire structure better. In any case, steel tubing provides multiple options to match the requirements for your project.

Consistent Measurements

Steel tube measurements are always consistent along their length. That means the whole thing will have a consistent thickness, diameter, and cross-sectional shape, making it easier to calculate its size and mass. When you order steel tubing, you can expect that the outside diameter and the wall thickness that you ordered will be the same for the entire product.

Telescoping

Steel tubing can be telescoped, or have parts sliding out from one another, and people often take advantage of this fact. You can attach several metal tubes, one smaller than the last one, to make them telescope. Telescoping tubing means that they can lengthen or shorten it with relative ease. It also adds to the flexibility of use and adaptability of the tubing.

If you need a telescoping metal tube, you might want to use a drawn-over mandrel thanks to its lack of a flash weld. These telescopic metal tubings work great if you need adjustability, such as for storage racks, flag poles, or camera mounts.

Rigidity

In addition to its natural strength, steel tubing is also known for its rigidity. You’ll find that metal tubes are very difficult to manipulate if you don’t have special equipment. There are some exceptions depending on the material, like copper and brass which are relatively soft metals. You can expect steel tubes to retain their shape for a very long time.

Key Takeaway

The advantages of steel tubing reinforce the idea that they are very useful materials that can be used in plenty of commercial and industrial applications. Projects that require a structural material that’s strong, rigid, precise, and adjustable would benefit from using steel tubing. They could support many structures from medical equipment, automobiles, appliances, and some construction applications. Take note that if you’re looking for something to transport gas or liquids, steel pipes are what you need.

If your project needs quality steel products, then we can help you. At Regan Industrial Sales, Inc., we deliver steel products that adhere to and even surpass international quality standards. Our trustworthiness is proven by our decades of operation and we are one of the top 150 corporations in the Philippines. Take a look at the variety of steel products that we offer here, or contact us here for any inquiries!