What are the top reasons to use H-beams in industrial buildings in the Philippines?

- Superior load-bearing capacity and stability

- High strength-to-weight ratio

- Ability to span a large distance

- Versatility in applications

- Durability and long service life

Overview

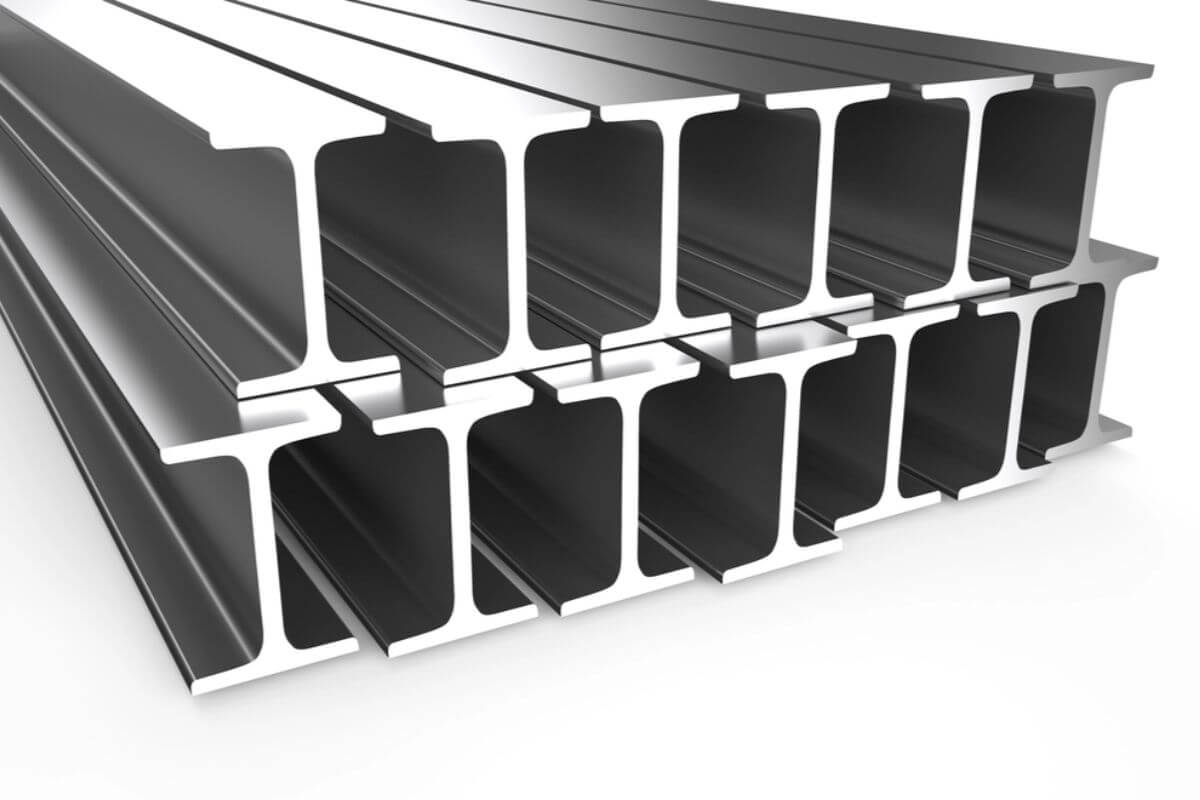

- H-beams offer strength, durability, and versatility, ideal for industrial buildings in the Philippines. Their high load-bearing capacity, low weight, long-span capability, and resistance to harsh environments make them essential for safe, cost-efficient, and disaster-resilient infrastructure.

- Regan Steel provides top-grade H-beams to meet the demands of large-scale construction projects.

As the Philippines continues to advance economically and industrially, sustainable development and public safety rely heavily on the strength and reliability of its infrastructure.

Given the country’s frequent exposure to natural disasters such as typhoons, earthquakes, and floods, it is essential to use structural steel materials engineered to withstand these challenges, especially as large-scale construction projects continue to rise.

In the sections that follow, we’ll explore the key reasons to use H-beams in industrial buildings in the Philippines and how they help meet these demanding conditions.

At Regan Steel, we provide high-quality wide flange beams, including H beams, and other innovative structural materials to support your construction projects.

Superior Load-Bearing Capacity And Stability

Facilities such as warehouses and logistics hubs are built to support not only their own structural weight but also the added load from heavy equipment, stacked goods, suspended systems, and constant activity. These environments often experience shifting loads, vibrating machinery, and continuous foot and vehicle traffic.

To maintain load stability and prevent structural stress, sagging, or long-term deformation, robust load-bearing support is essential. H beams are well-suited for this purpose—their wide flanges and thick web design help distribute weight evenly, reducing concentrated stress points.

This makes H beams ideal for use as columns, beams, and supports in high-demand facilities where safety and structural integrity are critical.

High Strength-To-Weight Ratio

In large-scale construction, particularly in areas with soft soil or high seismic activity, minimizing a building’s dead weight, the permanent load from structural elements like floors, walls, and beams, is essential. Excessive weight increases ground pressure and elevates risks during earthquakes.

H-beams address this challenge by providing high structural strength while maintaining a relatively low weight. Their efficient shape allows them to support substantial loads using less steel, which reduces the overall mass of the structure. This results in safer, more stable buildings that are not only easier and more cost-effective to construct but also better suited for long-term resilience.

Ability To Span A Large Distance

Large-scale operations such as distribution centers or assembly lines require wide, open interior spaces. Frequent columns disrupt workflow, limit the use of machinery like forklifts, and reduce layout flexibility. To achieve the clear-span design that many industrial facilities need, long-spanning structural components are essential.

The geometry of the H-beam allows it to span greater distances than standard beams without bending or compromising support. This means fewer interior supports are required, resulting in more open floor space and better design flexibility for evolving operational needs.

Versatility In Applications

Modern industrial projects vary widely in scale and function; some demand vertical expansion, others require wide horizontal spans or modular flexibility. To meet these diverse requirements, structural materials must be adaptable to different project types, from warehouses and power plants to bridges and aircraft hangars, while maintaining code compliance and high performance.

H-beams are incredibly adaptable. They can be used as vertical columns, horizontal beams, transfer girders, or even in custom-engineered frameworks. Their uniform shape and ease of fabrication make them a preferred choice for engineers seeking both strength and design flexibility across different industrial applications.

Durability And Long Service Life

Large structures in the Philippines must endure constant exposure to rain, humidity, and occasional flooding. These conditions can quickly degrade lesser materials. That’s why durability is a key requirement in structural design.

H-beams are made from structural steel, which offers exceptional strength and resilience. To protect against corrosion, these beams are often galvanized, which involves applying a layer of zinc to prevent rusting. This makes them ideal for the country’s wet climate.

Additionally, structural steel is non-combustible, meaning it doesn’t burn, warp, or fuel fires. While it can lose strength under extreme heat, proper fireproofing methods, such as coatings or encasements, can help maintain its structural integrity during a blaze.

For facilities meant to operate continuously and safely over the long term, H-beams are a sound investment.

Key Takeaway

As the Philippines continues to expand its infrastructure to support economic and industrial progress, the reality of both natural and manmade calamities remains a constant challenge.

In this context, the reasons to use H-beam in industrial buildings in the Philippines become clear; it’s about ensuring durability, safety, and long-term structural integrity.

At Regan Steel, we offer high-quality H-beams built for strength, durability, and performance under pressure, exactly what large-scale Philippine developments demand. Together, let’s build not just for today, but for a stronger, safer tomorrow. Contact us now to find a reliable solution for your construction project.