What key considerations should you make when using steel I-beams in the Philippines?

- Environmental factors

- Load-bearing requirements

- Transportation and site accessibility

- Material sourcing and quality assurance

- Local building codes

Overview

- Steel I-beams are vital to Philippine construction, offering strength and durability across various projects.

- To ensure optimal performance, developers must consider environmental conditions, load-bearing needs, transport logistics, material quality, and compliance with local building codes.

- Regan Industrial provides high-grade, certified I-beams designed to meet these requirements for safe, long-term structural integrity.

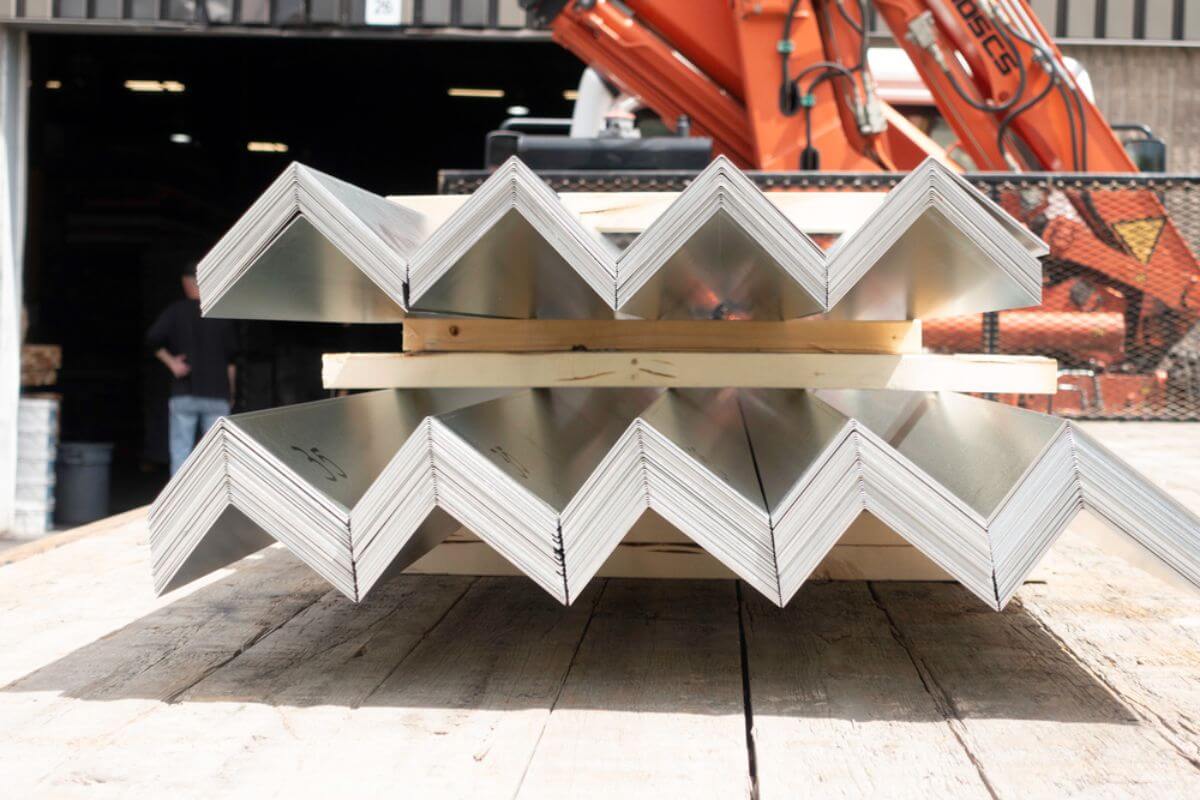

Steel I-beams are a fundamental component in Philippine construction, widely used in everything from residential buildings to large-scale industrial projects. Their strength and durability make them essential to the stability and longevity of modern structures. However, to ensure optimal performance, these beams must be matched to the specific demands of each development.

There are several considerations when using steel I-beams in the Philippines that builders must take into account. Whether the goal is to span wide sections or support substantial loads, understanding these factors is crucial to achieving safe, efficient, and structurally sound results.

Regan Industrial offers dependable components you can trust to perform reliably for any development. Read on to learn how they each shape the efficiency of your structure.

Environmental Factors

The Philippines is known for its unpredictable weather. Their consistent shifting can place significant pressure on the materials. Elements such as intense heat, heavy rainfall, and humidity all contribute to their fast deterioration. If left unaddressed, these elements can wear them down quickly and reduce their lifespan.

Steel beams with high resistance last longer against environmental wear. Sections with galvanized coatings prevent rust, while weather-resistant grades help them withstand long-term exposure. It’s important to use them under the right conditions to ensure they maintain their stability for longer periods.

Load-Bearing Requirements

I-beams have a high load-bearing capacity. However, each project has specific demands. Some require strong vertical support to handle multiple floors, while others rely on wide spans to accommodate heavier equipment. These conditions determine how much stress the beams will carry and how they must perform once they’re installed.

For instance, components that are designed for vertical loads are useful in supporting multi-story columns. Heavier-grade sections are the optimal choice for spanning large openings without support. Regan Industrial supplies steel I-beams suitable for these conditions, allowing developers to avoid structural inefficiencies throughout the project.

Transportation and Site Accessibility

Developers must plan logistics as early as the procurement stage. Roads are often busy in the country, so they must secure routes with proper clearances. Pre-arranging equipment and staging areas for weather-related issues also makes a significant difference by allowing teams to move the sections more efficiently.

Traffic issues in the Philippines often interrupt delivery schedules. Moving the materials to the construction site will take careful coordination since they come in large quantities that are difficult to transport. By planning transportation routes and timing, developers can keep up with construction timelines and avoid costly setbacks.

Material Sourcing and Quality Assurance

Material quality varies widely. When the steel grades are inconsistent, they can pose significant structural risks. Poorly sourced steel may lack the strength needed for critical applications. This could pose a danger to individuals who will eventually reside in the building or frequent the area over time.

For this reason, it’s crucial to consider getting steel beams from reputable suppliers. They are more likely to implement strict inspection protocols to make sure their products are safe for long-term use. Steel I-beams from Regan Industrial undergo thorough quality checks, ensuring they can perform in top condition. This level of assurance is especially important for projects with high safety requirements.

Local Building Codes

Government agencies, such as the Department of Public Works and Highways (DPWH), have set regulations and standards that every developer must follow. Policies such as those stated in the National Building Code all highlight the importance of using high-quality structural materials for the entire project’s safety and uniformity.

Failure to comply with these regulations can lead to legal setbacks. These include penalties and halted construction, which all stem from using substandard components. To avoid these issues, developers must ensure their I-beams are sourced from credible suppliers who can provide complete quality certifications. Verifying that the steel meets local standards will help them secure approval for their project at a faster rate.

Key Takeaway

Steel I-beams are a dependable component for frameworks, but to maximize them to their fullest potential, developers must consider factors beyond just their specifications. Addressing these key considerations when using steel I-beams in the Philippines is vital for building safe structures for long-term use.

Regan Industrial is your trusted supplier when it comes to high-grade steel sections. Contact us today to explore how our structural components can give your next build the full support it needs!