What are some of the advantages of deformed bars in reinforced concrete structures?

- Improved bonding capacity

- Increased load-bearing capacity

- Crack resistance and ductility

- Ease of handling and placement

- Corrosion resistant

- Compatibility with reinforcement accessories

- Sustainable construction

In the world of construction, reinforced concrete stands as a highly acclaimed material, renowned for its exceptional strength and durability. It achieves this through the combination of concrete’s compressive strength and the tensile strength provided by steel reinforcement.

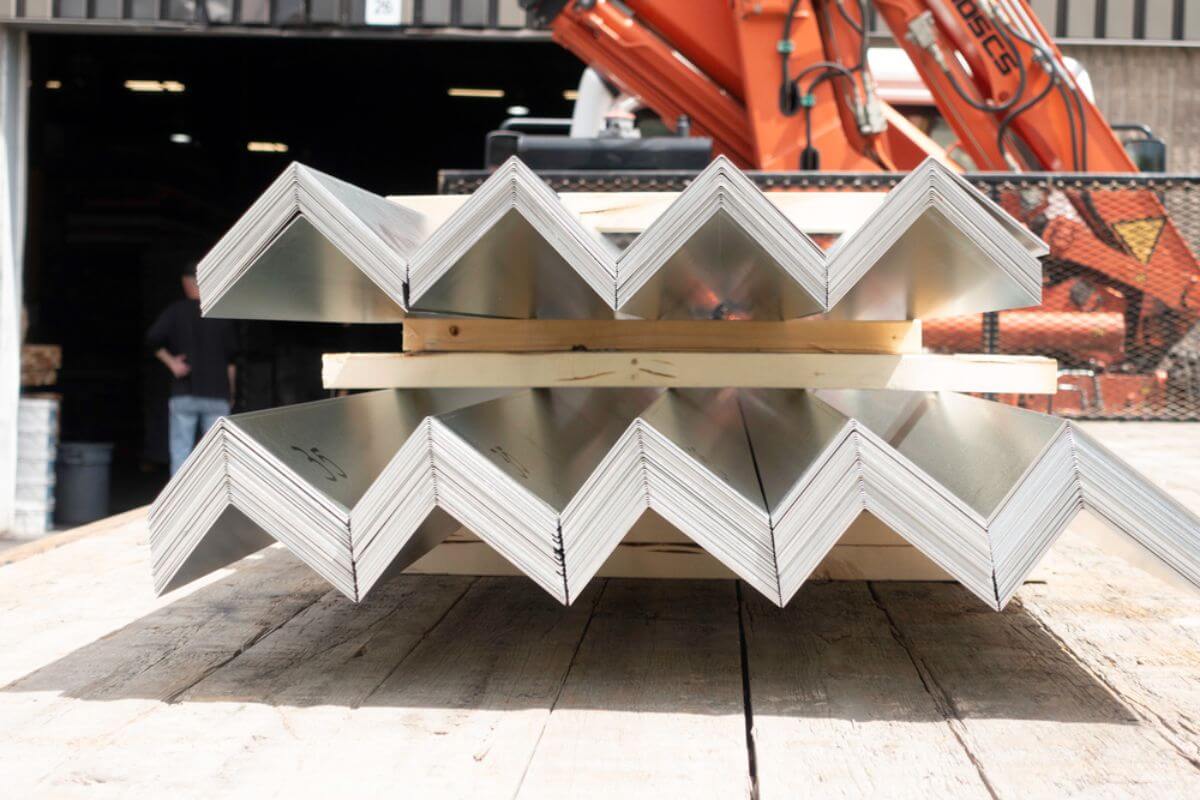

Among the key components of reinforced concrete structures are deformed bars, commonly referred to as reinforcing bars or “rebars.” Deformed bars play a crucial role in enhancing the structural integrity of reinforced concrete elements, ensuring their long-term durability and safety. In this article, we will delve into the advantages of deformed bars and shed light on how they contribute to the overall strength and stability of construction projects.

Improved Bonding Capacity

The surface of deformed bars is patterned with deformations, such as ribs, lugs, or indentations. These deformations create a mechanical bond between the steel reinforcement and the surrounding concrete, increasing the interlocking strength and preventing slippage or separation under loads.

The improved bond ensures efficient transfer of stress between the two materials, making the reinforced concrete structure more robust and resistant to cracking and structural failures.

Increased Load-Bearing Capacity

Deformed bars offer a significant advantage over plain, smooth bars with their higher tensile strength. This enhanced strength allows deformed bars to withstand greater loads, making them ideal for reinforcing concrete structures. The deformations present on the surface of these bars increase the contact area with the concrete, resulting in a more efficient and even distribution of the load.

Consequently, reinforced concrete structures incorporating deformed bars exhibit a higher load-bearing capacity, enabling them to support heavier loads and resist external forces, such as earthquakes or high winds.

In seismic events like earthquakes, the ground undergoes intense shaking, causing buildings to experience vibrations. These vibrations impose dynamic forces on the structure, subjecting it to substantial stress and strain. The deformations on the surface of deformed bars play a vital role in making structures earthquake-resistant. By creating a mechanical bond with the surrounding concrete, these deformations enhance the bond strength, effectively preventing slippage or separation under seismic loads.

As seismic waves pass through a structure during an earthquake, they induce bending and shearing forces. The presence of deformed bars with their larger contact area promotes effective dissipation and distribution of these forces throughout the structure. This characteristic prevents localized failure and significantly reduces the risk of catastrophic structural collapse.

Crack Resistance and Ductility

Deformed bars offer improved crack resistance and ductility to reinforced concrete structures. The surface deformations act as anchor points, inhibiting crack propagation, making them essential in earthquake-prone regions and under dynamic loads.

The presence of deformations also enhances the bars’ ductility, allowing them to undergo substantial deformation before failure. This ensures the structure’s load-carrying capacity even after the formation of initial cracks, resulting in a more resilient and durable construction. Deformed bars provide crucial advantages in minimizing crack propagation and maintaining structural integrity, particularly in high-stress and seismic-prone environments.

Ease of Handling and Placement

Deformed bars are available in various sizes and shapes, making them versatile and easy to handle during construction. The deformations on the bars’ surface provide a better grip for workers, facilitating the placement and positioning of reinforcement in complex structural configurations.

Moreover, the deformations help in maintaining the proper spacing between bars, preventing congestion and ensuring adequate concrete cover, which is essential for the long-term durability and corrosion resistance of the reinforced concrete structure.

Corrosion Resistant

Reinforced concrete structures benefit from the corrosion resistance provided by deformed bars. Manufacturers often apply a protective coating, such as epoxy or zinc, to these bars, further enhancing their ability to withstand corrosion. The deformations on the bar’s surface play a crucial role in anchoring the protective coating, creating a robust barrier against moisture, chemicals, and other corrosive elements.

This corrosion resistance significantly prolongs the lifespan of the reinforcement, ensuring the reinforced concrete structure’s long-term durability. By reducing the risk of corrosion-related damage, the use of deformed bars minimizes maintenance requirements and associated costs, making them a cost-effective solution, especially in environments exposed to corrosion-inducing factors like coastal areas or chemical pollutants.

Compatibility with Reinforcement Accessories

Various reinforcement accessories, such as couplers, mechanical splices, and headed bars, find compatibility with deformed bars. These accessories are responsible for establishing efficient and reliable connections between different reinforcement elements, thereby enhancing the overall structural integrity of reinforced concrete structures.

By facilitating seamless connections, these accessories contribute to the ease of construction while reducing labor requirements. The compatibility of deformed bars with reinforcement accessories also offers flexibility in design and construction, allowing for the implementation of innovative and efficient reinforcement systems.

This compatibility opens up possibilities for incorporating precast concrete elements and modular construction techniques, further enhancing the construction process and overall efficiency of the structure.

Sustainable Construction

These steel bars also boast sustainability features. Using deformed bars in reinforced concrete structures aligns with sustainable construction practices. Reinforced concrete is a recyclable material, and deformed bars can be easily separated from the concrete during demolition for recycling.

By incorporating recycled deformed bars, the environmental impact of construction projects can be minimized. Additionally, the durability and resilience provided by deformed bars contribute to the longevity of the structure, reducing the need for frequent repairs or replacements.

This results in reduced material consumption, energy usage, and overall carbon footprint, making deformed bars an environmentally-friendly choice for reinforced concrete construction.

Key Takeaway

There are several advantages of deformed bars that contribute to the overall strength, durability, and safety of reinforced concrete structures. As the demand for durable, resilient, and sustainable infrastructure continues to grow, deformed bars will remain a vital component in the design and construction of reinforced concrete structures, providing a solid foundation for safe and durable buildings.

As one of the leading suppliers of steel products in the Philippines, Regan Industrial Sales Incorporated offers a vast selection of steel products to suit your needs. From pipes and tubing to bars, rods, plates, and more, our meticulously crafted steel products are produced with the latest technology and expertise.

With nearly 50 years of experience, we have built a reputation for delivering top-notch products at competitive prices. Visit our website or contact us today to explore our complete range of steel products and trust us for all your steel product needs in the Philippines.