What are the differences between pre-engineered steel buildings vs conventional buildings?

- Process

- Design

- Labor Costs

- Materials

- Foundation

- Expansion and Repair

- Durability

If you’re in the process of deciding how to construct a building, you may be stuck on one part of the process: which would be better for your project? When weighing the benefits of pre-engineered steel buildings vs conventional buildings, knowing the different requirements when it comes to materials and methods can help in tipping the scale from one option to another. Read on to learn more about the differences between these two construction methods.

Process

For conventional construction, the process occurs step by step. Excavating the site, laying down the foundation are the first steps before the building frames are put into place. Each step must be completed before moving on to the next, which makes scheduling an integral part of the process. If one step is delayed, it affects the end date of the project. This means that the efficiency of this process is largely dependent on the efficiency of the labor force.

For pre-engineered steel construction, the process can be finished at a quicker pace. The parts for assembly are designed and fabricated off-site, and later delivered to be assembled. Workers then unpack these fabricated steel sections and set them up based on the design given to them, and the sections are connected using steel bolts.

Design

Conventional buildings can take on more complex and unusual designs. This is because each component in this method can be designed and fabricated from scratch. However, while it can meet more complicated design specifications, it also costs more and produces a lot more construction waste in the process.

Pre-engineered structures can meet simpler designs with ease. Each component is made to be mass-produced and quickly made, so fabricating specialty sections isn’t usually done by manufacturers. Rather, each component is fabricated to meet a specific and uniform design. These designs use standard sections to be quickly erected once they are delivered to the construction site.

Labor Costs

Conventional structures take much longer to be constructed, so this method ends up having higher labor costs. They use more construction workers to haul material and create the structure, walls, floors of the build. These buildings also need thorough inspection and maintenance at every step of the process, as well as multiple subcontractors for the needed materials, which adds to the labor needed to finish this type of construction.

The pre-engineered process eliminates the need for architects or engineers for designing the building, as the building is already using a set design. These structures also need fewer construction workers and subcontractors to create the finished product. As a result, this method has a quicker turnaround and can often be completed within two months, which lowers labor costs.

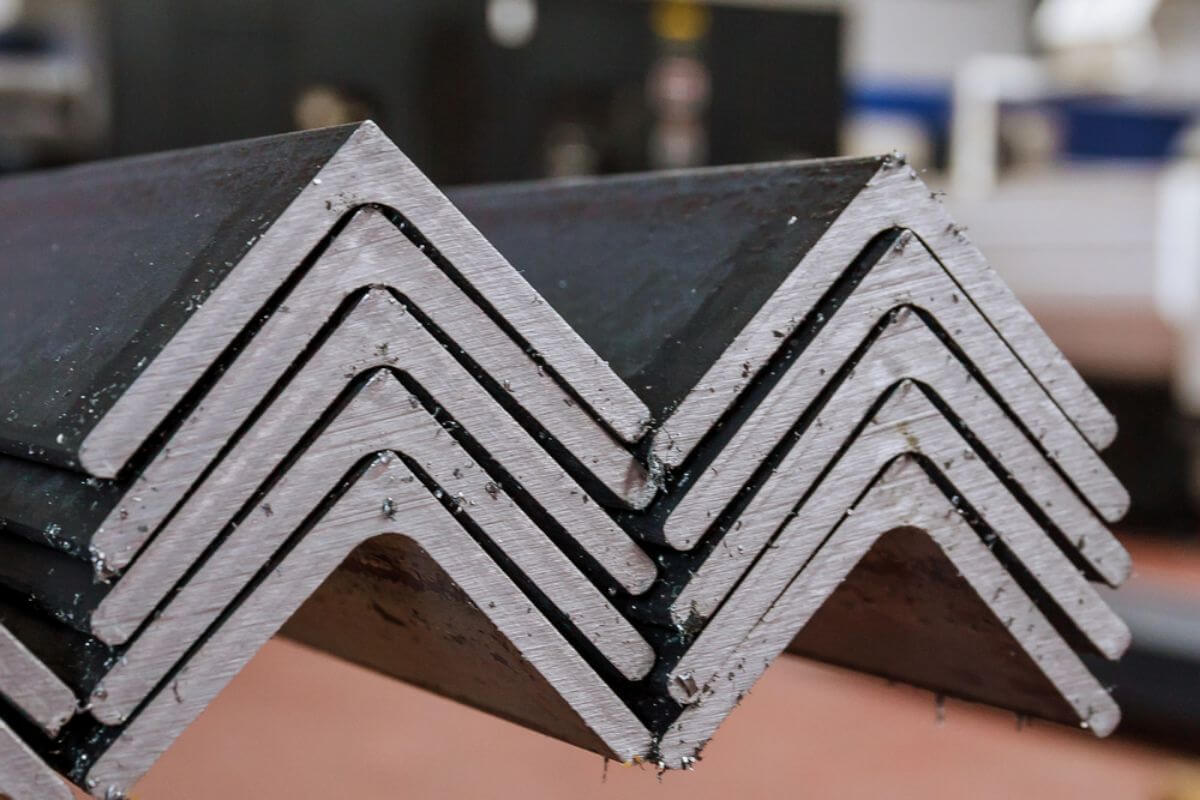

Materials

Conventional buildings use materials that are typically sourced from multiple vendors and subcontractors. This can create complicated logistics operations as well as potential quality control problems as the material is coming from different suppliers. Additionally, the materials will have to be standardized for the project either at the time of purchase or on-site. Standardizing them at the time of purchase can be costly while standardizing them onsite will need additional labor and time.

For pre-engineered frames, the materials are ordered on an as-need basis. Each section to be used in the construction will be created when ordered, which minimizes the number of materials used. Each section is also sourced from the same manufacturer, which makes logistics and quality assurance much easier for the project.

Foundation

The foundations of a conventional building need to be able to withstand tonnes of concrete and steel. The weight of this type of structure is quite heavy, so a robust concrete foundation is needed to support its weight. However, there is no 100% accurate way to predict the final weight of a finished conventional structure, so the foundation design needs to be overestimated. Otherwise, the foundation will be too weak and will cause structural issues later on.

The foundation of a pre-engineered building is much more simple. This is because this type has the advantage of weighable components. This means that everything can be calculated to give a final weight. Also, because these sections use less steel, it results in a much lighter finished product that needs a less robust foundation.

Expansion and Repair

Adding expansions or making repairs to conventionally made buildings can be difficult, as the design needs to take into account the original frame of the structure. The details and quality of the frame can create complications when doing additional construction on an existing structure.

The same cannot be said for pre-engineered buildings. They are made to be eminently expandable and customized for new uses. For extensions, new sections can easily be ordered and attached to any side or on top of the existing building. Repairs are also easily made as the same section can be ordered from the same manufacturer to replace the damaged part.

Durability

Conventional structures are highly durable. These buildings can last for decades — some have even lasted for more than a century! The lifespan of conventional buildings can be extended if the appropriate maintenance is given to them. Additionally, these structures are designed with the region and environment in mind, and can typically withstand natural forces such as earthquakes and storms with little problem.

Pre-engineered steel buildings tend to be less sturdy, but have come a long way since their initial form. They are now much more durable and can last for years. They can also be disassembled and moved if needed. Every building made by this method is designed to meet local architecture and construction standards, so they can also hold out against heavy rains and seismic activity.

Key Takeaway

Not every construction method will be ideal for your project. To make the right decision, you have to weigh the differences between pre-engineered steel buildings vs conventional buildings. Each difference is a factor that will impact how your project will go, and if it will be able to meet your project’s specifications and budget. Understanding the contrasts between the two options will show which technique will be more equitable for your project.