What is modular construction and what should you know about it?

- Reduced Negative Environmental Impact

- Time-Efficient

- Better Construction Quality

- Safer Work Environment

Construction projects normally happen on the site itself, meaning the building is constructed where it’s supposed to stand. But there’s a different option that lets workers do the actual construction at a separate venue: modular construction. What is modular construction exactly?

Modular construction for prefab homes and buildings is the method where the structure is produced in a plant or factory and it is built-in parts or modules to be assembled later on the site. It may seem unusual, but it offers numerous benefits which are why it has become a popular option for many construction projects. Although modular building isn’t very well-known and may seem like a modern innovation, it has actually been around for a very long time, with the first instance recorded in the 1830s.

This off-site construction process has proven very useful because the resulting structure is indistinguishable from on-site constructions. Some even claim that modular buildings are much stronger and more structurally sound than traditionally constructed buildings.

It proves that the merits of modular construction are notable, making it a viable option for your next construction project. If you want to learn more about this, keep reading below for some things you should know about modular construction.

Reduced Negative Environmental Impact

Building construction produces plenty of waste. It shouldn’t be surprising considering the amount and variety of materials that are needed in construction. However, other than excess building components, it also becomes a source of hazardous materials that may negatively impact the environment. This includes materials such as asbestos, lead, paint thinners, and mercury.

The modular building process is more environmentally-friendly than traditional construction because it is conducted under plant conditions. Inventory and building materials are better controlled within the factory, and thanks to this, most materials are recycled and protected. Modular buildings can also be disassembled, relocated, or even refurbished. This means that even at the end of its life, modular buildings still generate little waste.

Time-Efficient

Modular construction projects get finished in around half the time that traditional construction projects do. A big factor here is the ability to get on-site work (like site development and foundations) and building constructions that are done simultaneously. The overall project completion would be over 30% – 50% sooner than normal.

This method also eliminates the risk of any weather delays. Whenever there is inclement weather, onsite construction would stop, but modular construction, being indoors, doesn’t need to be hampered. You can add traffic delays and other on-site disruptions to the list of what can be avoided in modular construction. Overall, modular construction saves a lot more time while maintaining the same standards as those of traditionally-constructed buildings.

Better Construction Quality

Because it relies heavily on planning and a good understanding of modular construction methods, the process often uses advanced building information modeling (BIM) software. The digitalization of building plans will almost always improve the design itself, and workers will find the most cost-efficient way to finish construction. Working indoors means that everyone is operating under better conditions and employees would be working more comfortably. And any good manager or supervisor would know that this would bring out better quality work.

With the right materials, modular buildings match the standards that most other buildings adhere to. Anyone who was not involved in the construction process would not be able to determine whether a building underwent modular or traditional on-site construction. Also, the modules are built to hold out against the rigors and challenges of transportation. As an added effect, it also makes the building itself stronger once completely integrated.

Safer Work Environment

Working in a factory as opposed to working on-site means there are lower chances of accidents and injuries for the workers. Not to mention that working on-site means working on an entire building at once, but with modular construction, which is done in an indoor setting, you work on only one portion at a time. This allows you to handle smaller parts and deal with smaller responsibilities at a time compared to dealing with a whole building. It also lessens costs when it comes to compensating employees for possible injuries.

Key Takeaway

Being familiar with modular construction allows you to consider it as an option for your construction projects. Designers, architects, and engineers are always looking for more innovative ways to get the job done. If you want a more time-efficient process that’s environmentally friendly and produces high-quality results, then modular construction is definitely a good choice.

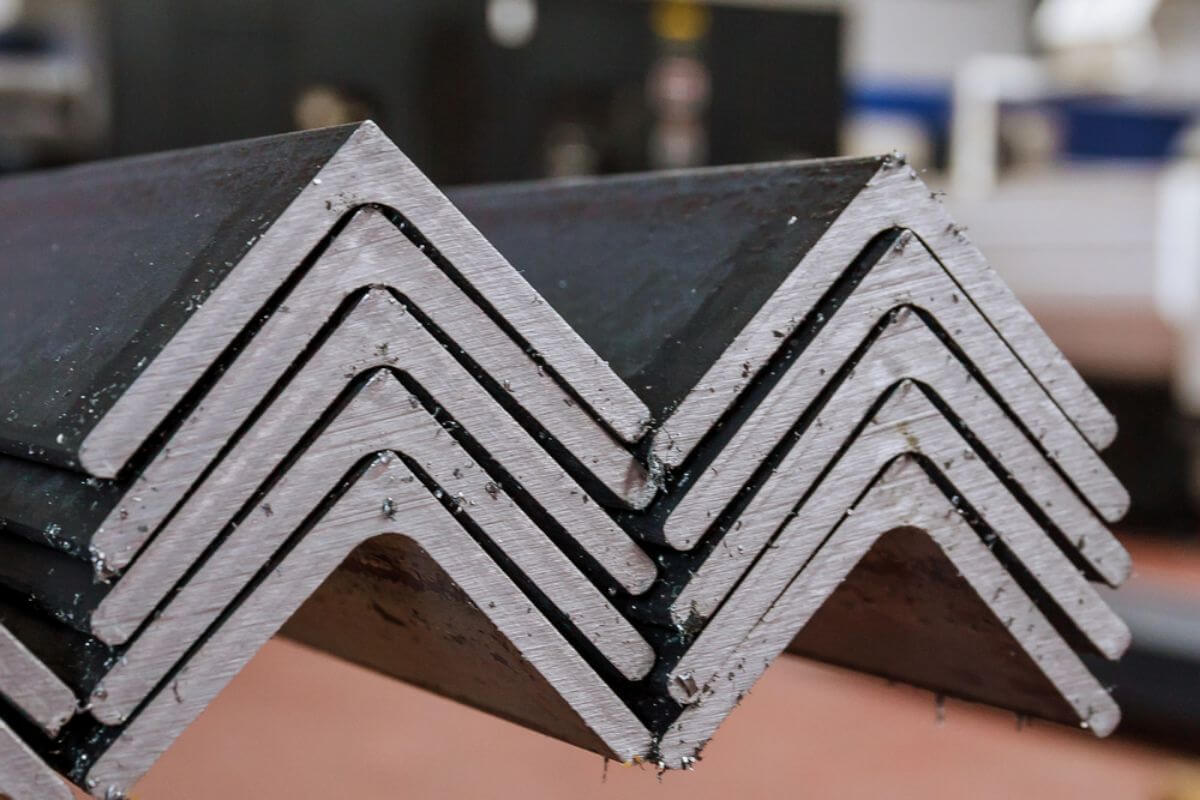

However, the strength and integrity of your structure rely on the quality of the materials you use. Using less than ideal materials for modular construction could spell disaster for everyone involved. Thankfully, we at Regan Industrial Sales, Inc. offer a wide variety of affordable steel products that are trusted, tried, and tested by many in the Philippines. If you have any more inquiries, you can always contact us here!