What are the different types of factory-built structures?

- Modular Construction

- Permanent Modular Construction

- Temporary Modular Construction

- Panelized Construction

- Hybrid Modular Construction

Is your only experience with prefab buildings seeing sections of a home being hauled on the backs of trucks? Then you might think that’s all there is to this kind of construction — but, there are more types of factory-built structures than you think.

With prefab buildings, it can be as simple as putting together some ready-made panels into a simple warehouse, or as complex as erecting intricate modules to create a luxury home.

Read on to learn about all the different ways manufacturers can make a prefabricated building!

Modular Construction

Modular construction is the most well-known method of making prefabricated buildings and one that you may have seen done before. With this method, modules — or “boxes” of a building are all built in a factory. These are then wrapped and taken by trucks to a construction site.

Each module is specially designed to slot in with other modules in the design, so they’re relatively easy to erect and assemble on-site. Some modular construction may even include things like siding, built-in features, appliances, flooring, and more to streamline construction — though these additions cost more than simple modular construction.

There are two different methods that manufacturers use to make modular buildings, which are:

Permanent Modular Construction

Under this category, modular buildings and their components are built for permanent use. This means that they are not made to be moved around once they are set up. Instead, they stay at the same location where they were assembled. This method is often used for prefab houses, multi-story buildings, schools, and the like.

Permanent modular construction is much like traditional buildings but offers the many benefits of prefabrication construction, such as decreased labor and material costs. These kinds of factory-built structures are settled on permanent foundations — usually concrete — or retrofitted to an existing building. They are also made with more durable materials, such as steel, to remain usable for a longer time. However, it does take some more time to construct and assemble than other modular solutions.

Temporary Modular Construction

Also known as non-permanent construction, this method creates “relocatable buildings.” They are designed to have more mobility, which allows them to be transported or repurposed to different building sites as needed.

This type of factory-built structure is ideal for projects that need to quickly create functional spaces, yet only need such buildings for a short period. These include buildings like container van offices, temporary housing, field clinics, stores, temporary commercial spaces, and the like.

Since they need to be moved around quite often, they don’t need to be set on permanent foundations. And, they are typically constructed with materials like rigid plastic, wood, and lightweight metals. This allows them to be adequately tough and durable, but light enough to easily relocate. However, this method offers fewer options for layout, design, and customization than Permanent Modular Construction.

Panelized Construction

Panelized construction is another method for making factory-built structures. In it, manufacturers make panel-like components, which function somewhat like pieces of a jigsaw puzzle. When brought onsite, these panels are designed to quickly snap into place through the use of bolts and other joinery and are used to create a complete building.

Some panelized homes arrive on-site with windows, siding, roofing, and doors already installed, while others may have those components installed afterward. Whether these panels come with additional aspects depends on the manufacturer and building design.

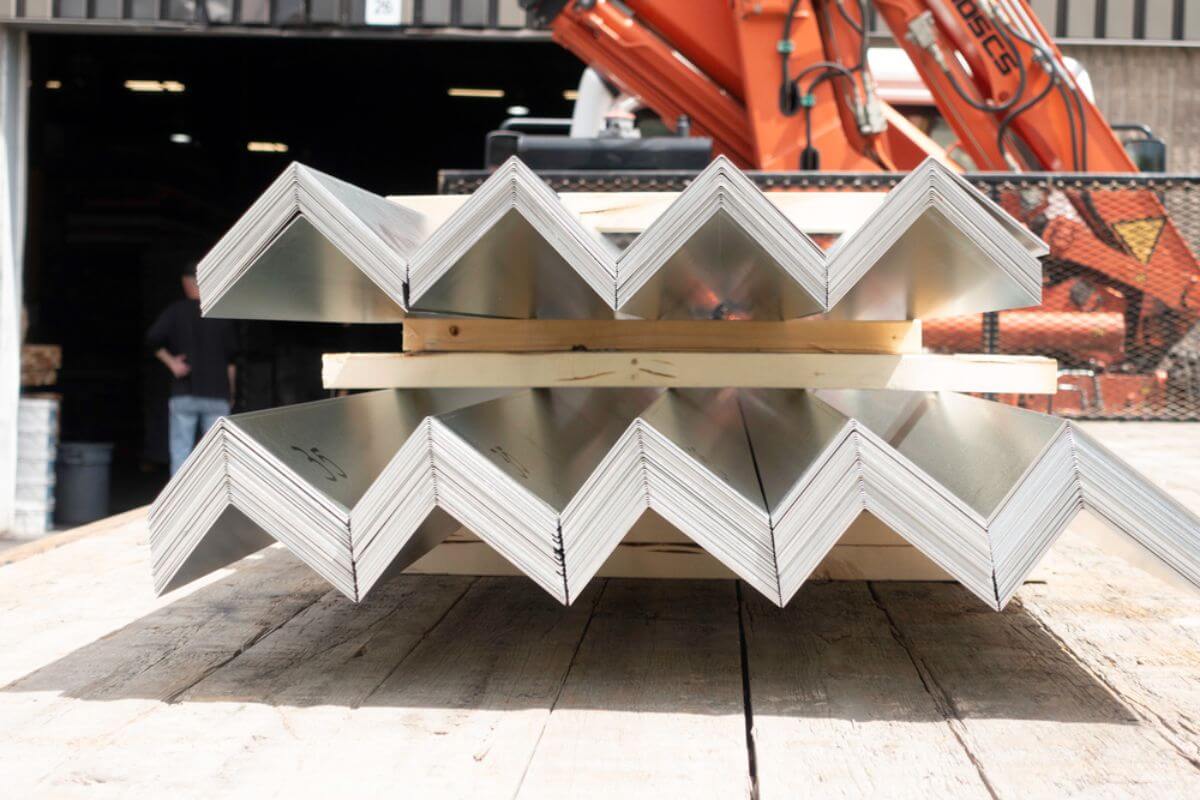

Panelized construction can also accommodate structural insulation — creating a type of panel that we call Structural Insulated Panels (SIPs). These panels typically have a fused layer of insulation foam in between two metal boards. This removes the need for wood framing while providing air infiltration. This type of panel is energy efficient, and can be constructed and installed very quickly. It also requires fewer interior walls, which helps in creating open-concept areas.

Hybrid Modular Construction

Hybrid modular construction is an approach that combines the flexibility and shipping advantages of panel construction, with the productivity benefits of modular construction. Depending on the building, this prefab solution may be the best choice.

For example, you can use modular rooms to create functional areas, such as a kitchen and bathroom for a prefab home. Meanwhile, the rest of the structure can be completed with standard panel sections. This means that certain parts of the structure can be more intricate and finished on the factory floor, but the production time for the whole structure is streamlined — all without limiting the finished product.

Key Takeaway

There are many types of factory-built structures to choose from for your project — each with numerous benefits to offer for your building. If you’re having trouble choosing which prefab solution works best for your application, reach out to Regan Industrial Sales, Inc. today. As a reputable and knowledgeable steel manufacturer, we have just the right steel solutions to help you achieve success with your construction project!