What are the differences between structural steel and reinforced concrete?

- Material

- Strength

- Cost-effectiveness

- Availability

- Fire-resistance

There is much debate on structural steel vs reinforced concrete and which material is the better choice for construction projects. Each has its own benefits. While concrete may make use of readily-available materials and aggregates, structural steel has an edge due to its high tensile strength, weldability, and toughness. Architects and building designers take these factors into consideration before choosing the right material for the job.

Steel and concrete differ in a number of features, such as the type of material, strength rating, cost-effectiveness, availability, fire resistance, and many more. All of these will have an impact not only on the design, but also on the quality, and maintenance requirements of any given project. Read on to learn more.

Material

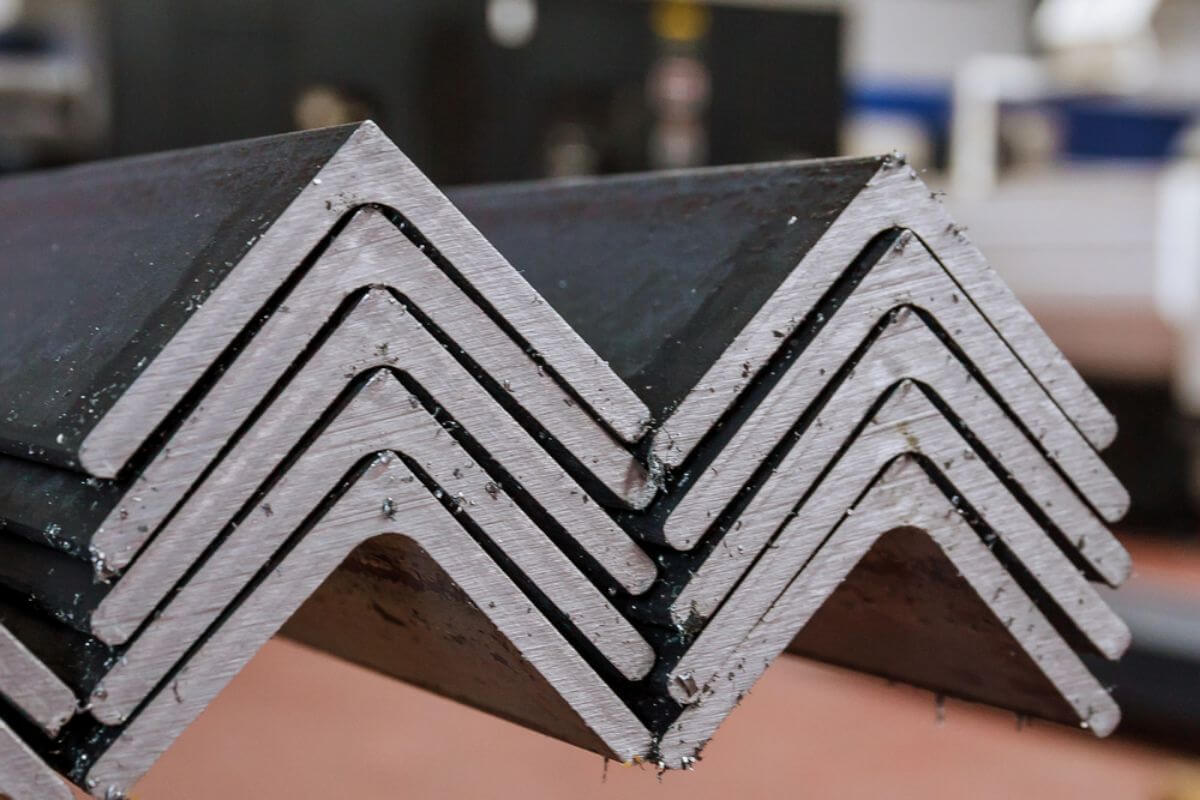

Structural steel can be further classified into various types, mild carbon or high carbon steel, depending on the composition. Mild steel refers to products designed for structural purposes, but they can also be found in automotive components, wires, fencing material, or even decorative furniture. High carbon steel on the other hand may contain upwards of 0.61% of carbon. Some applications include carbon steel pipes, building frameworks, studs, trusses, or tool steel.

As for reinforced concrete, the primary ingredients may vary, but it generally contains a combination of aggregates, pastes, and other natural pulverized materials that have been mixed with water. The reinforcing takes place through the steel rebars that are also added to the mix. This is done to improve the tensile strength and allow the concrete to become more flexible. Reinforcing steel bars also reduces the amount of concrete material needed for a building foundation or column.

Strength

Structural steel and reinforced concrete have similar strength ratings. The values for structural steel can range anywhere from 400 to 500 MPa. For reinforced concrete, it can reach compression strengths of up to 415 MPa, but on its own, it may only be limited to up to 70 MPa.

Both materials offer stability for any type of structure. Concrete buildings can provide excellent protection against impact or compression forces during natural disasters like earthquakes. Similarly, when structural steel is used as a building framework, it also offers high resistance against impacts that can cause damage to a building. It also protects against wind uplift which can cause a building’s roofing to detach from the ceiling structure during heavy wind loads.

Cost-Effectiveness

Although steel is a common material, it involves complex manufacturing and fabricating processes before it can be fit for wide distribution. Structural steel is not naturally occurring — it starts off with the mining of iron ore which is smelted into a carbon-based solution that creates the steel.

After removing all of the other impurities, the solution would have to be cast into ingots, slugs, or billets before they can be transformed into sheet piles, roofing material, structural beams, rods, or pipes.

Compare the process above with how concrete is produced. The primary materials are the aggregates which have been broken up from various rocks and minerals. After processing and sifting these aggregates through a crushing equipment, the materials will be mixed with other additives. Combining it with water can already prepare it for use.

Keeping all of these in mind, reinforced concrete may be the more cost-effective material for small-scale applications that aren’t really impacted by highly-damaging forces. Using structural steel may be expensive, but it can minimize the need for repair and maintenance — reinforced concrete may eventually become brittle over time due to natural wear and tear.

Availability

The components needed to manufacture structural steel are readily available. As mentioned before, natural aggregates and steel rebars are its main composition. Steel rebars are affordable and can be recycled indefinitely without losing too much of their original properties.

Granted that structural steel may involve a more sophisticated method of fabrication, they are used commonly across various industries. In fact, global crude production of steel even breached 1,800 million tonnes in 2019.

Likewise, old structural steel members may also be re-milled because their its recyclability. Some structural steel components that you see across modern buildings nowadays can have up to 25% of recycled steel material.

Fire Resistance

Both structural steel and reinforced concrete are fire-resistant, making any structure built from these materials stable. Under high temperatures, however, the properties of both materials may be negatively impacted.

For example, subjecting a steel beam to extreme thermal variations can cause internal stresses, which can form cracks on the material. This may also affect its tensile strength and hardness, causing higher sensitivities under heat, despite being non-combustible.

Meanwhile, reinforced concrete isn’t typically installed on its own. Surrounding materials like plastic or wood may even cause fire to spread much more quickly, in the event of an emergency.

Despite this, structural steel is still the better choice, due to its non-combustibility and high fire-resistance rating. These materials can aid in limiting the spread of fire in a single location, keeping building occupants free from harm.

Key Takeaway

Between structural steel vs reinforced concrete, structural steel offers higher strength, fire resistance, and excellent recyclability. Reinforced concrete, on the other hand, uses far more affordable materials. They’re also a cost-effective option for small projects like residential spaces, warehouses, or any bare-bones structure.

Understanding all of these differences is important before you can choose the most suitable material. Ultimately, it depends on the type of building design that you’re planning. It’s also not uncommon for structural steel and reinforced concrete to be combined in a single construction setting.