What are the differences between concrete stairs vs steel stairs?

- Strength and durability

- Versatility

- Build time

- Cladding

- Maintenance

- Overall costs

- Aesthetics

A staircase is an essential part of any kind of building. It’s used in all structures, be it residential, industrial, or commercial buildings. This is why designing the right staircase for your building is a crucial step — particularly when selecting the right materials to make it with.

When it comes to staircases, the material should be structurally sound, economic, and fitting for the building’s overall aesthetic. And, when we consider the best materials, it comes down to two contenders: steel and concrete.

But what are the differences between concrete stairs vs steel stairs? In this article, we give an in-depth look at what each option has to offer.

Strength and durability

Both materials are strong and durable, though they present their own advantages depending on how they are used.

Steel is one of the sturdiest, strongest metals that you can use to build a staircase. This material has high tensile strength, so they are extremely resistant to heavy loads. Certain processes, such as galvanization, increase their resistance against corrosion, making this material even more durable. Thus, steel staircases can be long-lasting even in outdoor environments with extreme weather conditions.

On the other hand, concrete is also a strong and durable material. It has a high compression strength, which means it resists forces from pushing the material together, thus preventing deformation. However, it doesn’t have high tensile strength — which means it often has to be reinforced with rebar to have the same tensile strength as steel. Concrete is also fire-resistant and absorbs vibration, so it’s a great option for fire exit stairwells, hospital staircases, and the like.

Versatility

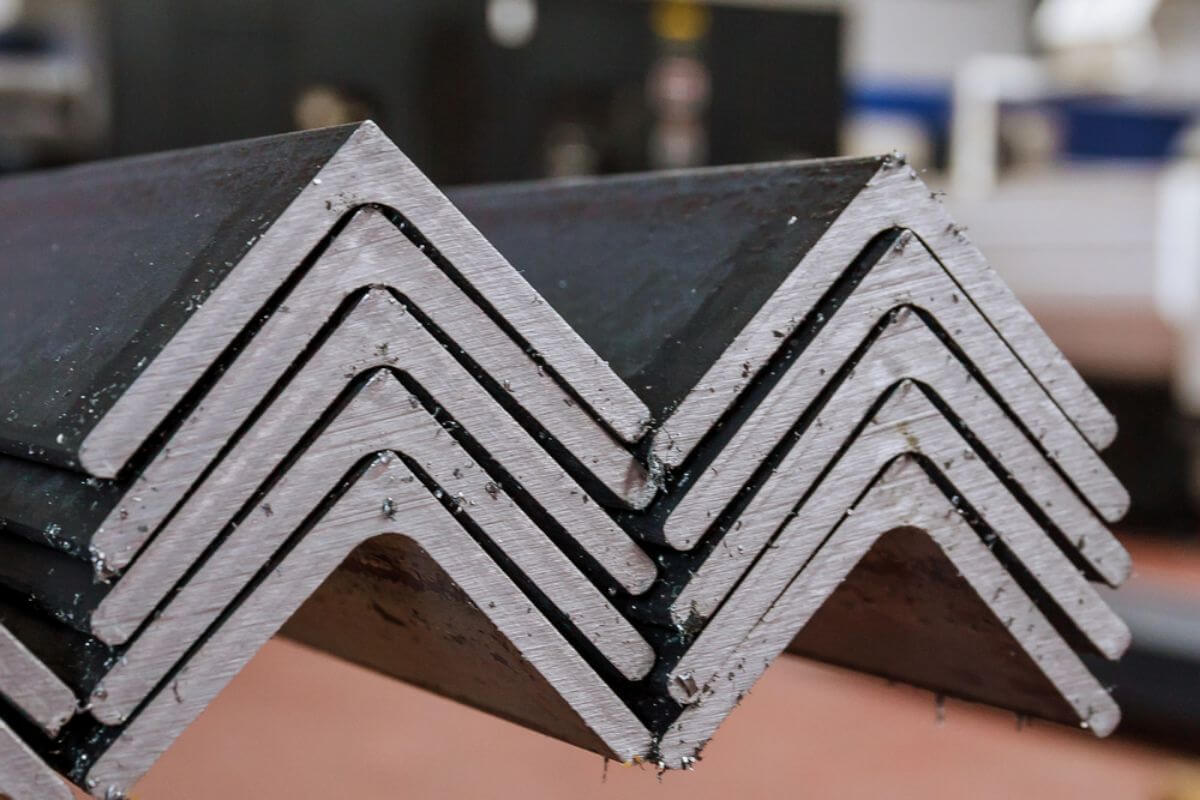

There is a bigger array of design options for your staircase when you use steel. This is because steel is often manufactured in various shapes and styles, and therefore can be used to create anything from traditional staircases to helical ones, among others. When using custom-made steel parts, you also have a variety of options concerning layout, treads, handrails, connections, and more while designing your staircase.

While concrete can be used to make a variety of shapes, this material can be difficult to cast — and the results are not as accurate as manufactured steel pieces. So, achieving different designs while meeting building regulations and specifications can be more time- and effort-intensive.

Build time

Aside from the casting process, builders also spend a lot of time preparing the foundation, shuttering, and setting up reinforcements for a set of concrete staircases. This is a lengthy process — and if your project is running on a tight schedule, it may be difficult to get done on time.

A steel staircase, on the other hand, can be quickly manufactured, delivered, and installed. In most cases, this whole process can be faster than constructing a concrete staircase. This will free up your team to work on other areas of your construction project.

Cladding

Cladding is a process done to give staircases reinforcement or give them a new look without needing to replace the structure. Both concrete and steel staircases can be clad with a material of your choices, such as wood, tiles, or other metals.

That said, cladding steel staircases is much easier than doing the same on concrete. Since steel is built more precisely, exact measurements can be taken for fitting your cladding material. This ensures accurate sizing and manufacturing of your cladding materials, lessens production and installation time, and results in a high-quality build.

With concrete stairs, templates need to be made from the steps and risers to manufacture cladding material correctly. However, concrete stairs are rarely 100% consistent or accurate, which makes the cladding process much harder. Additionally, fixing cladding on concrete can be risky, as drilling into the material could damage the structural integrity of the staircase.

Maintenance

Both materials are generally easy to maintain. Steel and concrete, whether installed indoors or outdoors, only need regular cleaning to prevent corrosion. If coated or galvanized, then steel may need even less cleaning, as it has higher corrosion resistance.

For both materials, you can use pressure washers, mops, sponges, and mild cleaning products and detergents to remove any grime, dirt, and residue from the staircase. Using tools like mops and sponges should also help you from damaging the finish your staircase has.

Overall costs

The overall price of manufacturing and installing a steel staircase is less than that of a concrete staircase. This is because steel, in general, is a very cost-effective material for manufacturing. Furthermore, steel staircases, as we mentioned, are easier and quicker to construct than concrete — resulting in fewer labor costs. Pre-built modular components and sections can also help reduce the overall costs of making a steel staircase even more. Concrete stairs take a lot of preparation to build, including preparing the foundation, building a framework, placing metal reinforcements, and more.

Aesthetics

When it comes to aesthetics, steel offers more advantages when it comes to steel. Not only is it a versatile material to work with, but it is also considered a contemporary and modern one. This makes it ideal for offices, homes, and commercial buildings, where aesthetics is an important factor for any structure. Other materials, such as wood and stone, can also be easily integrated into steel staircases to provide a customized look.

On the other hand, concrete staircases tend to be more functional than aesthetically pleasing. This is why they are typically built to serve the basic purpose of stairs in outdoor areas. Otherwise, they are placed in hidden parts, such as fire escapes, basements, and the like, where they are usually out of sight.

Key Takeaway

When weighing concrete stairs vs steel stairs, the winner is clear. Steel staircases, more often than not, are the ideal choice when it comes to functionality, aesthetics, needs, budget, and more.

Whether you plan to install these in your home, your office, or some other new building, be sure to contact a professional — Regan Industrial Sales, Inc.! We deliver a wide variety of high-quality steel products, fit for residential, industrial, and commercial use. Get in touch with our team today to get advice for your project, or receive a quote!